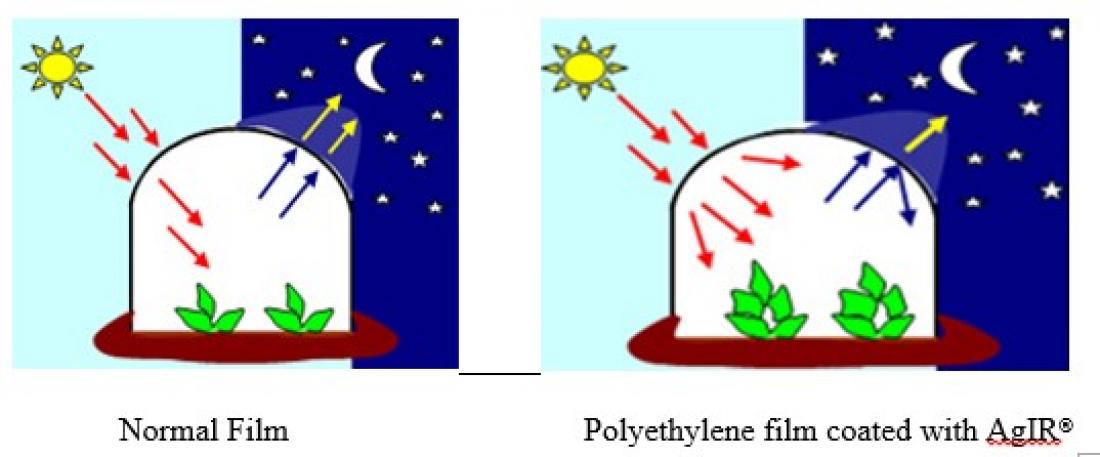

Schematic showing comparison of normal film (left) and polyethylene film coated with AgIR® (right). The polyethylene film coated with AgIR® retain energy and prevents IR radiation loss at night.

Growing vegetables under tunnels or greenhouses covered with the so-called thermic films (plastic films opaque to infrared (IR) radiation, especially between 3000-14000 nm) is known to have a greater vegetative development, earlier harvests of greater quality and more abundance. These films present additional advantages, such as the reduction of risk of frosts when the greenhouse is not heated, and an important reduction of the energy consumption when a system of heating is used. Both improvements of the films are due to the lower heat losses by radiation.

The use of standard mineral fillers or additives, such as calcined kaolin, calcium–magnesium, along with others which have been normally used to increase the IR opacity of low-density polyethylene (LDPE) and other greenhouse films, accelerates the photodegradation of the film as well as moderately increases the haze condition and diminishes the light transmission.

This newly developed nanocomposite coating lacquer by University of Malaya’s researchers, Ir. Dr. Ching Yern Chee and her team, has the desired characteristics of high far infrared (FIR) effectiveness and high transmission levels of photosynthetically active radiation (PAR). FIR effectiveness measured by fourier transform infrared showed that the AgIR® coating lacquer has greatly improved the thermic effect of agricultural film. The novel improvement of FIR radiation is important due to their relationship with energy retention and the “Greenhouse Effect” which can retain the long wave IR radiation from rapid loss at night.

The use of this specialized infrared barrier systems allows control of the climatic conditions inside plastic greenhouses such as those of small and large tunnels. During the day, slightly decrease the temperature inside greenhouses by blocking near infrared radiation (NIR; 750 -1400 nms) outside thermal greenhouses. While at night, increase the temperature inside greenhouses by creating a barrier to far infrared radiation (FIR; 3,000 -14,000 nms) which is reflected by the soil from rapid loss. These modified conditions optimizes the growing conditions, thus allowing farmers to extend the production season, increase yields and maximize profit.

AgIR® lacquer makes it possible to produce economical agricultural greenhouse film that can withstand severe agricultural chemicals levels and assure a service life of more than three years even under intense sunlight. The use of this special formulated UV blocker also protects greenhouse film against low-wavelength solar radiation by preventing the oxidation of the polymer chain of polyethylene from the damaging effects of these rays and prolongs its usage. Blocking out the UV will help to block out a significant part of the visible range of insects. UV-blocking materials have properties to filter the UV radiation (280-400 nm) interfering with the vision of insects and in consequence, their behavior related with movement, host location ability and their population parameters. BioAgUV® strongly absorbs UV-radiation up to 390 nm.

The benefits of applying AgIR® Coating lacquer on conventional agricultural greenhouse

film:

1) Earlier harvest, higher yield and better quality and uniformity of crops.

2) Resulting in:

• Reduced evapo-transpiration, which increases sugar and taste quality of produce

• Substantial energy savings when heating greenhouses

• Minimize temperature fluctuation:

3) During the day, slightly decreases temperature inside greenhouses by blocking near infrared radiation (NIR; 750 -1400 nms) outside thermal greenhouses

4) During the night, increases temperature inside greenhouses, by creating a barrier to far infrared radiation (FIR; 3,000 -14,000 nms) reflected by the soil from rapidly loss.

5) Inhibit degradation of PE polymers in greenhouse film by blocking UV radiation

6) Contribute, along with Photosynthetically Active Radiation (PAR), to the organoleptic properties of vegetables, fruits and flowers.

7) Reduction of the population of white flies, thrips, miners, aphids and other harmful insects. Reduction of such populations also results to reduction of viruses which can be vectored to cultivars by these insects.

8) Control of the spread of certain diseases, by reduction of the sporulation of the relevant pathogenic fungi (example: Botrytis).

9) Contribute efficiently in "Integrated Pest Management" and help to reduce the usage of pesticides - benefits to both consumers and growers.

Limitation of the existing Greenhouse materials:

1. Polyethylene (PE)

- IR Effectiveness 15-20%

- Transparency PAR 70-75%

- Haze 16%

- Limitations: Low thermic effect & low transparency

2. EVA copolymer

- IR Effectiveness 65-75%

- Transparency PAR 80-90%

- Haze 13%

- Limitations:

a) Increase accumulation of dust and blocking of films

b) Reduce mechanical properties, especially creep, when used in hot climates.

3. Special termic LDPE (Fosfate)

- IR Effectiveness 80-88%

- Transparency PAR 60-65%

- Haze 17-28%

- Limitations:

a) Accelerate photodegradation of polymer matrix

b) Reduce visible light transmission & PAR

c) Increase haziness

d) Discoloration

4. Special termic LDPE (Silico-alluminate)

- IR Effectiveness 65-70%

- Transparency PAR 60-65%

- Haze 20-30%

- Limitations:

a) Accelerate photodegradation of polymer matrix

b) Reduce visible light transmission & PAR

c) Increase haziness

d) Discoloration

5. EVA (Silico-alluminate)

- IR Effectiveness 70-76%

- Transparency PAR 70-75%

- Haze 15-24%

- Limitations:

a) Accelerate photodegradation of polymer matrix

b) Reduce visible light transmission & PAR

c) Increase haziness

d) Discoloration

This invention has been patented (Patent number: MY-150386-A).