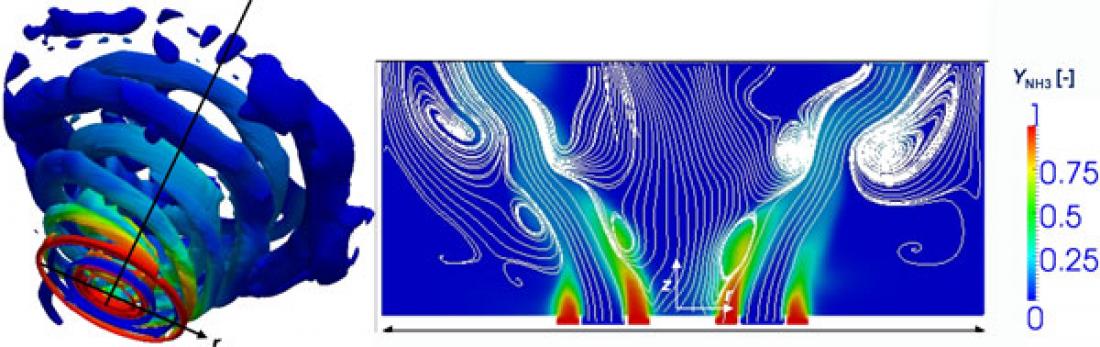

Left: Vortex structures of swirling flows. Right: Mixing pattern of two ammonia streams with the air stream near the swirlers, located at the bottom of the figure. Colours indicate ammonia mole fraction distribution, with higher amounts of ammonia molecules in red, and lower amounts in blue.

Researchers in Japan have identified a way to reduce harmful emissions produced by ammonia fuel. It involves swirling the gas with air as part of the power generation process. The finding helps advance research into ammonia as an alternative to carbon-based fuels for cars, airplanes, and power generation facilities. Ammonia (NH3) is a compound that contains one nitrogen and three hydrogen atoms. It is under investigation as an alternative fuel source for several reasons. It contains a lot of hydrogen, but is less expensive and less flammable than pure hydrogen, making it safer to transport. Production plants already exist because ammonia is widely used in fertilizers. So far, ammonia has been considered as a fuel when blended with gasoline, diesel, hydrogen and methane fuels to reduce the proportion of carbon-based fuels and their emissions that contribute to climate change. Developing ammonia as a pure fuel source remains a challenge, in part because relatively high levels of harmful nitric oxide emissions are produced during the combustion process. Nitric oxide is known to be harmful to human health, contributes to ozone depletion, and when it reacts with other compounds, contributes to acid rain and atmospheric warming. A team from the Institute of Fluid Science at Tohoku University in Japan used supercomputers to run 'large eddy simulations' to analyse how ammonia fuel behaves under different combustion conditions, and to see if it is theoretically possible to reduce nitric oxide emissions. Specifically, they analysed what happened when ammonia was swirled together with air inside a theoretical combustion chamber under different pressures. They compared the results with those of ammonia and air premixed before entering the combustion chamber, which is known to produce fewer nitric oxide emissions at high fuel to air ratio conditions. They found that swirling not one, but two streams of ammonia gas with one stream of air reduced nitric oxide emissions to levels on par with premixed processes. Making the volume of the two ammonia streams between the innermost and outermost swirlers uneven - 60 percent and 40 percent of the total injected fuel, respectively -- led to a more even distribution of fuel and air throughout the combustion chamber, which produced lower nitric oxide emissions. Still, emission levels were higher than the Japanese environmental regulations for gas power turbines. The researchers plan to next test if injecting air downstream of the combustor further reduces emissions.