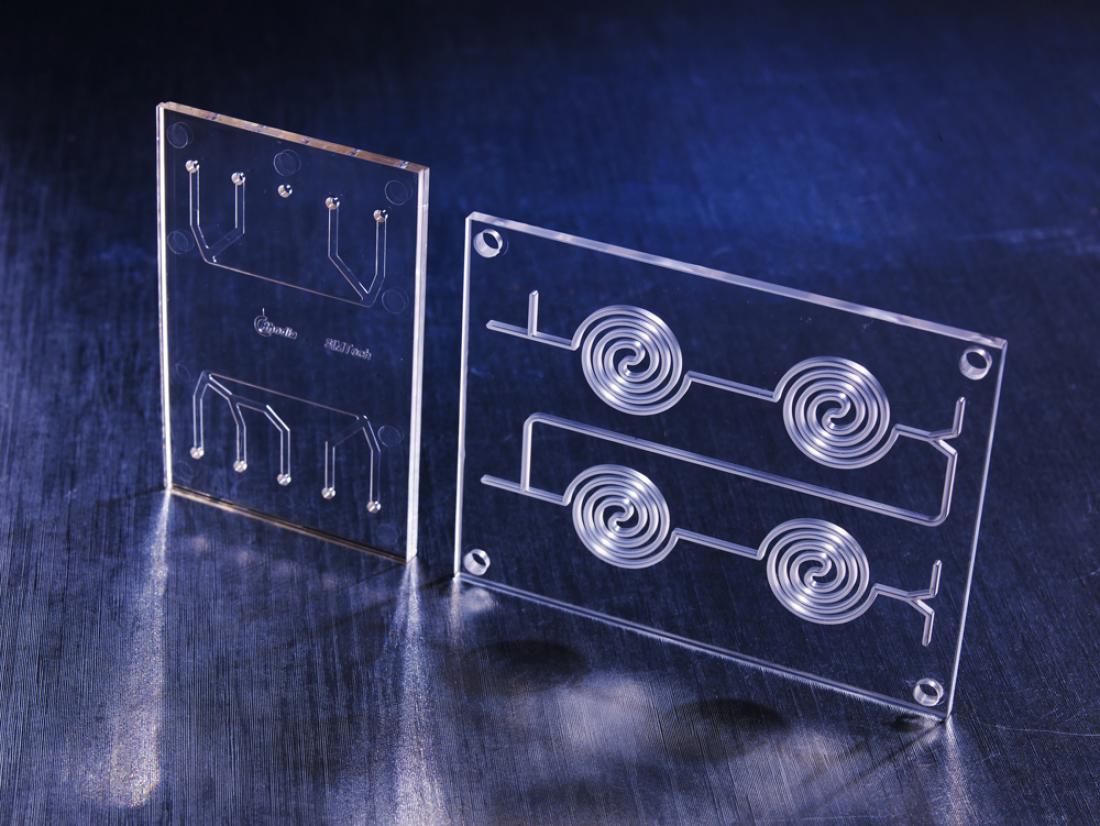

Microfluidics devices

The new foundry enables Singapore precision engineering and electronics companies to foray into industries ranging from point-of-care, clinical diagnostics, pharmaceutical and life science research, energy, water quality monitoring to chemical processing. The global microfluidic device market is estimated to grow three-fold to US$5 billion in 2016.

The Singapore Institute of Manufacturing Technology (SIMTech), a research institute of the Agency for Science, Technology and Research (A*STAR), launched the SIMTech Microfluidics Foundry (SMF) today. SMF offers an integrated spectrum of capabilities for developing and manufacturing of specialised and low-cost microfluidic devices for applications in healthcare, biomedical, pharmaceutical, energy, water quality monitoring and chemical processing. ReflectingA*STAR’s strategic investments in R&D of innovative high-value manufacturing solutions, this will make Singapore a focal point for public-private sector microfluidic devices investments, R&D and manufacturing.

The Government continues its steadfast investments in growing R&D in Singapore. $16.1 billion Singapore dollars has been earmarked under the Research, Innovation and Enterprise 2011 to 2015 Plan or RIE 2015. This is an overall increase of about 20 per cent over the previous quinquennium and a commitment of 1 per cent of expected Gross Domestic Product (GDP) to public sector research and innovation. With this increased commitment, there is also increased expectation and emphasis on economic impact and fostering commercialisation of R&D. Singapore aims to increase our gross expenditure on R&D (GERD) to 3.5 per cent of GDP by 2015.

The global microfluidics market is estimated to grow to US$5B in 2016 (Yole Developpement 2011, Microfluidic Substrates Market and Processing Trends), driven largely by the advancement of biotechnology and microtechnology. Although Singapore does not presently have a microfluidic industry, Fluidigm and microfluidic start-ups such as CAMTech, Clearbridge Biomedics, JN Medsys, Molbot and Fluigen have set up operations in Singapore for medical/life science applications, seeding the growth of such an industry in Singapore. A key enabling technology that cuts across multiple industry sectors, microfluidics is an important capability that has yet to be exploited.

A*STAR aims to exploit opportunities in the microfluidics space through harnessing our strengths in multi-disciplinary research across the biomedical, physical and engineering sciences. One of the unique and significant value propositions of A*STAR is the spectrum of capabilities that we have and our ability to organise the relevant parts in a synergistic way both within and beyond A*STAR to develop meaningful public-private partnerships.

The microfluidic industry, with its diverse applications spanning from point-of-care, clinical diagnostics, energy, water quality monitoring and chemical processing, is an ideal avenue for diversification and growth for the Singapore precision engineering and electronics industries.

Although microfluidic devices offer rapid analysis and diagnostic functions, the current high manufacturing cost, lack of design and manufacturing standards for large volume manufacturing of microfluidic devices inhibits its widespread commercial adoption. Furthermore, microfluidics with its diverse applications and the distinct requirements for each application make it difficult to standardise for mass production. Currently, many biochips are fabricated using silicon wafers or glass slides. The special processes required during the manufacturing of these silicon-based biochips prove to be expensive for disposable applications. Polymer materials, on the other hand, are better suited for fluidic sample analyses and fabrication can be achieved in bulk at a fraction of the cost for disposable applications. Through its competencies and capabilities to address these challenges, SMF can help nurture and grow the microfluidic industry in Singapore.

SMF provides the emerging microfluidic industry an integrated spectrum of competencies from design, simulation, prototyping to scalable technology development for mass production of polymer-based microfluidic devices. Companies can leverage on the integrated suite of services provided by SMF to reduce cost and improve efficiency as well as translate their laboratory concepts or prototypes to market in the shortest time cost-effectively by accessing the existing competencies and capabilities of microfluidic research in Singapore and Switzerland.

Dr Lim Ser Yong, Executive Director of SIMTech said, “The SIMTech Microfluidics Foundry provides a low-risk environment for companies to place their capital-intensive investments for testing and implementing microfluidic technology solutions. It also offers a strong base for precision engineering and electronics companies to expand and pursue growth in other industries, assisting in the development of microfluidic products for biomedical, pharmaceutical and chemical companies and help start-ups to accelerate its commercialisation process by providing robust manufacturing capabilities and innovative microfluidic solutions.”

Today, SIMTech signed three research agreements with Rhodia Asia Pacific, CAMTech Management and Molbot to develop high-throughput microfluidic tools for applications and product development in pharmaceuticals; for water quality monitoring and for gene cloning respectively. SIMTech also signed a Memorandum of Understanding with CAMTech Innovations (UK) and Clearbridge Biomedics to jointly develop design and manufacturing technologies of microfluidic devices for life science companies as well as intends to collaborate on development of manufacturing technologies and solutions for microfluidic devices for potential commercial use respectively. These microfluidic R&D commitments reflect the confidence of industry in SMF’s competencies and capabilities, seeding a growing microfluidic industry in Singapore.

Dr Mario El-Khoury, CSEM Chief Executive Officer, said: “The SIMTech Microfluidics Foundry is a successful outcome of the research collaboration between CSEM and SIMTech. Today, SMF is a milestone for Singapore to grow the microfluidic industry. We look forward to furthering our collaboration with SMF to advance the microfluidic technology and its applications that impact the quality of life, such as healthcare, biomedical and life science research.”

#######################################################################################################

About the Agency for Science, Technology and Research (A*STAR)

The Agency for Science, Technology and Research (A*STAR) is the lead agency for fostering world-class scientific research and talent for a vibrant knowledge-based and innovation-driven Singapore. A*STAR oversees 14 biomedical sciences and physical sciences and engineering research institutes, and six consortia & centres, located in Biopolis and Fusionopolis as well as their immediate vicinity. A*STAR supports Singapore's key economic clusters by providing intellectual, human and industrial capital to its partners in industry. It also supports extramural research in the universities, and with other local and international partners.

About the Singapore Institute of Manufacturing Technology (SIMTech)

The Singapore Institute of Manufacturing Technology (SIMTech) is a research institute of the Science and Engineering Research Council (SERC) of the Agency for Science, Technology and Research (A*STAR). SIMTech develops high value manufacturing technology and human capital to contribute to the competitiveness of the Singapore industry. It collaborates with multinational and local companies in the precision engineering, electronics, semiconductor, medical technology, aerospace, automotive, marine, logistics and other sectors.

About Centre Suisse d’Electronique et de Microtechnique SA (CSEM)

CSEM, (Swiss Centre for Electronics and Microtechnology), founded in 1984, is a private applied research and development centre specialising in micro- and nanotechnology, system engineering microelectronics and communications technologies. It offers its customers and industry partners custom-made, innovative solutions based on its knowledge of the market and the technological expertise derived from applied research. CSEM's mission is to enhance the competitiveness of industry, particularly Swiss industry, by developing applied technology platforms in micro- and nanotechnologies and ICT and transferring them to the industrial sector.

#######################################################################################################

Media Enquiries

Singapore Institute of Manufacturing Technology (SIMTech)

Ms Melissa Loh

DID: 6793 8276

Mobile: 8499 6639

Email: [email protected]

ANNEX A

SIMTech MICROFLUIDICS FOUNDRY

The SMF provides a one-stop solution for microfluidic devices development. The unique microfluidic research facility is dedicated to R&D of the entire value chain of microfluidic devices manufacturing. Housed under one roof at SIMTech, it has competencies in all aspects of manufacturing from the complete microfabrication line for polymer microfluidic device design, fabrication, testing and characterisation to rapid prototyping and pilot manufacturing for large scale production.

The Foundry’s cleanroom facility occupies 350m2 in physical space with several process clusters namely structuring, metallisation, surface functionalisation, bonding and testing. It is equipped with the full range of measurement tools for mechanical, fluidic, optical and electrical characterisation of microfluidic devices and technical solutions on optimal material choice, fabrication process, fluidic architecture, interfacing structure and packaging scheme. The pilot production service offered by SMF assists companies to overcome high equipment, material and personnel overhead costs, significantly shortening the time-to-market and manage volume production of microfluidic devices.

ANNEX B

SUCCESS STORIES

SIMTech and Rhodia Asia Pacific, a French multinational chemical company, in a four-year partnership developed lab on chip devices and explored the development of new research tools for the home and personal care, oilfield and polymer industries. Areas of research include designing disposable microfluidic devices for measuring chemical reactions; characterising liquid properties and for complex flow of oil, water and gas. These devices have been delivered to Rhodia Lab of the Future (LOF), a special laboratory focused on developing high throughput tools in France. The development time for these chemicals has been drastically shortened with these high throughput devices as almost all the experiment are now automated, allowing more variables to be screened.

RESEARCH AGREEMENTS

Rhodia Asia Pacific to develop high-throughput microfluidic tools for applications and product development in pharmaceuticals to speed up product development with reduced resources and cost. Rhodia is driving the application and the conceptual design of the specific applications in pharmaceutical and chemical domain. SMF will be developing microfluidic design and manufacturing technologies to meet the needs of specific applications.

“Through its staff, SIMTech has demonstrated high level of commitment, dedication and technical competencies in microfluidic research and development in our past four years of collaboration in diverse microfluidic applications. Arising from these, Rhodia has made a strategic decision to continue the collaboration through working with SMF to accelerate the development of microfluidic technology in more specialised areas of applications and, to realise the potential benefits of microfluidic in our business”, said Dr Galder Cristobal, Rhodia-Novecare Asia Pacific R&D Director, Rhodia Asia Pacific Pte Ltd.

CAMTech Management to develop high-throughput microfluidic tools for applications and product development in pharmaceuticals; for water quality monitoring.

“Lab on a chip applications are extremely promising but are confined mainly in the research phase within laboratories. The new SIMTech Microfluidics Foundry (SMF) will accelerate the development and manufacturing of many applications for end-users. Over the past year, the facilities and support of SIMTech have been fundamental in driving forward microfluidic devices projects. We are excited to work with SMF to design, develop and commercialise innovative lab on a chip devices. We will continue working and developing innovative new microfluidic devices with SMF,” enthused Dr Kuok MengHan, Managing Director, CAMTech Management Pte Ltd.

Molbot is a local start-up company supported by SPRING Singapore through the Technology Enterprise and Commercialisation Scheme (TECS). It develops labs on chips for diagnostic and biomedical research.

Molbot is collaborating with SIMTech to produce small, powerful, automatic, labs on chips, making state-of-the-art biomedical research abilities more readily available. Using such a device, it will be possible to test food for Salmonella in 24 - 30 hours, instead of the 3 days it takes now. "The SIMTech Microfluidics Foundry is an excellent R&D partner for us, as it can rapidly prototype our designs in a manufacturing-ready form, “said Dr Patrick Gilligan, Managing Director, Molbot Pte Ltd.

MEMORANDUM OF UNDERSTANDING

1. CAMTech Innovations (UK) to jointly develop design and manufacturing technologies of microfluidic devices for life science companies.

“CAMTech Innovations looks forward to promoting SIMTech Microfluidics Foundry and its design and development services. The Memorandum of Understanding between the two organisations underlines a long-term partnership that signifies a strong commitment to developing the market,” said Dr Kalyan Sarma, Managing Director, CAMTech Innovations.

2. Clearbridge Biomedics intends to collaborate on the development of manufacturing technologies and solutions for microfluidic devices for potential commercial use.

Clearbridge BioMedics (“CBB”) is a spin-off from the National University of Singapore (NUS), and an incubatee of Clearbridge Accelerator, a Singapore Government backed high-technology incubator. Leveraging on a microfluidic biochip invention, CBB is commercialising the world’s first Circulating Tumor Cells (CTC) system that can isolate and most importantly retrieve viable CTCs from whole patient blood taken intravenously. CTCs are extremely rare cells that have detached from a primary tumor and are circulating in the bloodstream. Capturing and counting CTCs enables clinicians to conduct cancer diagnostics, screening, post-cancer monitoring that is invaluable to allow clinicians to make timely and life-saving decisions. Most impressively, the system is able to capture wholly intact CTCs in their viable and native state from patient whole blood, allowing clinicians to conduct critical genetic analysis to optimise cancer therapies – paving the way for personalised cancer treatment.

“Our ClearCell™ CTChip® microfluidic biochip enables the next generation non-invasive 'liquid-biopsy' for researchers, clinicians and patients, paving the way for better cancer care management,” stated Mr Johnson Chen, Managing Director of Clearbridge BioMedics. “By working with SIMTech, we have the opportunity to develop and, more importantly, shorten our development time for our subsequent generations of our CTChip®. With SIMTech’s capabilities to efficiently manufacture microfluidic devices, we will be able to have a robust manufacturing process and technology that can scale for mass commercialisation in future.

Both SIMTech and Clearbridge BioMedics will be leveraging on each other’s strength and expertise, with a common goal to develop advanced manufacturing and design capabilities for microfluidic devices," said Mr Johnson Chen, Managing Director of Clearbridge BioMedics