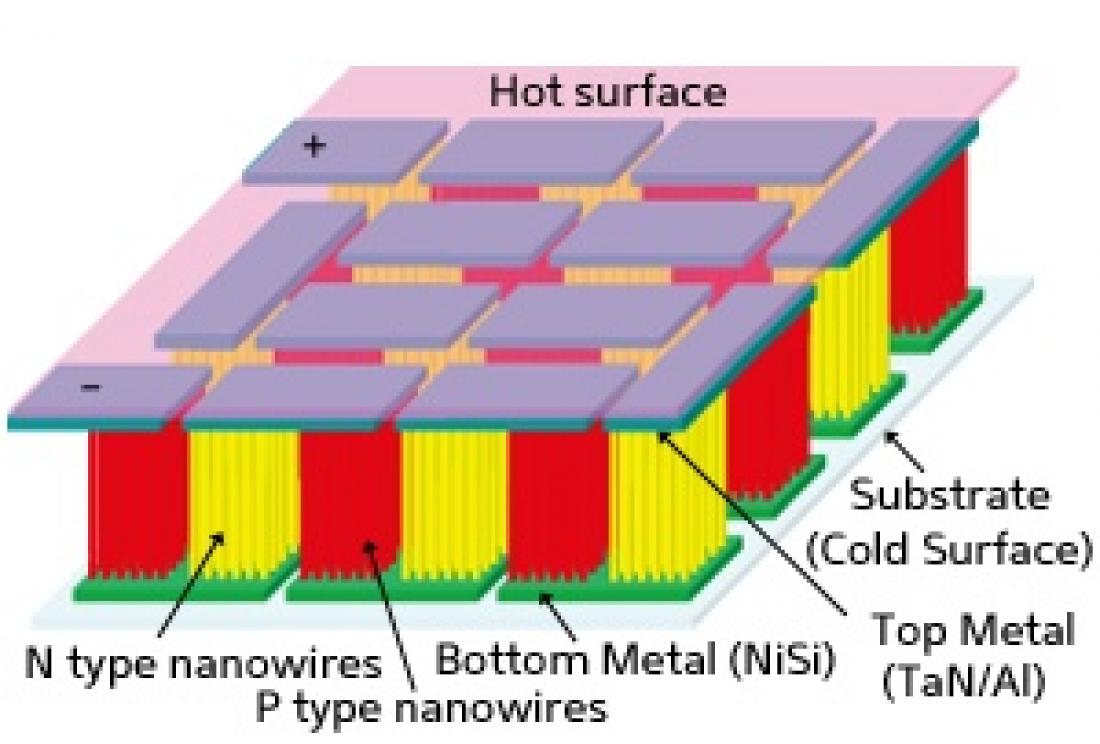

The new thermoelectric generator uses silicon nanowire ‘legs’ to collect heat from hot spots in electronic circuits

Electronic devices often develop ‘hot spots’ that can become detrimental to performance. Much research has focused on developing methods to cool the system, or, even better, convert the excess heat to electricity by exploiting the thermoelectric effect — where a thermal gradient induces the movement of charge carriers. However, previous attempts at building chip-level generators have failed because the incorporated materials were not compatible with the technology used for constructing integrated circuits, such as complementary metal oxide semiconductors (CMOS).

Navab Singh and co-workers at the A*STAR Institute of Microelectronics and the National University of Singapore1 have now created a nanoscale thermoelectric generator (TEG) using silicon nanowire arrays. Silicon, which is compatible with the base materials in CMOS, had previously been discounted due to its poor performance as a generator in bulk form, but it has proved far more effective on the nanoscale.

“Silicon nanowires have much better thermoelectric properties than the parent material, because they have much lower thermal conductivity,” Singh explains. “Also, state-of-the-art equipment is already available for processing silicon. Therefore, if thermoelectric coolers and energy harvesters can be fabricated using silicon nanowires, they can be low-cost, scalable, high-yield devices.”

The researchers constructed their TEG by connecting together two different metal plates using vertical legs made from alternating bunches of n-type silicon nanowires, in which excess electrons carry the charge, and p-type nanowires, in which the charge carriers are ‘holes’ caused by missing electrons (see image). According to Singh, the biggest challenge was connecting the nanowires to the metal plates to allow a low resistivity contact and provide the optimum thermoelectric performance. To do so, they adapted established techniques from CMOS fabrication. “However, high contact resistance on the wire tops remains an issue and our design needs further improvements,” says Singh.

As an electrical generator, a TEG could be used to ‘self-power’ a section of an electronic circuit. “Further, they can be used to generate power and supplement batteries in most high heat flux systems like automobiles, semiconductor lasers and photo detectors,” suggests Singh. They could also provide an efficient, low-cost cooling system for removing hot spots.

Singh believes nanoscale TEGs could also be used in medical science to power implants in the human body: “A nanowire thermoelectric power generator fits the bill perfectly. They can be scaled to appropriate size and since they lack moving parts, they are reliable and could span the lifetime of the patient. Energy could then be extracted using the temperature gradient between the body and the environment.”

The A*STAR-affiliated researchers contributing to this research are from the Institute of Microelectronics