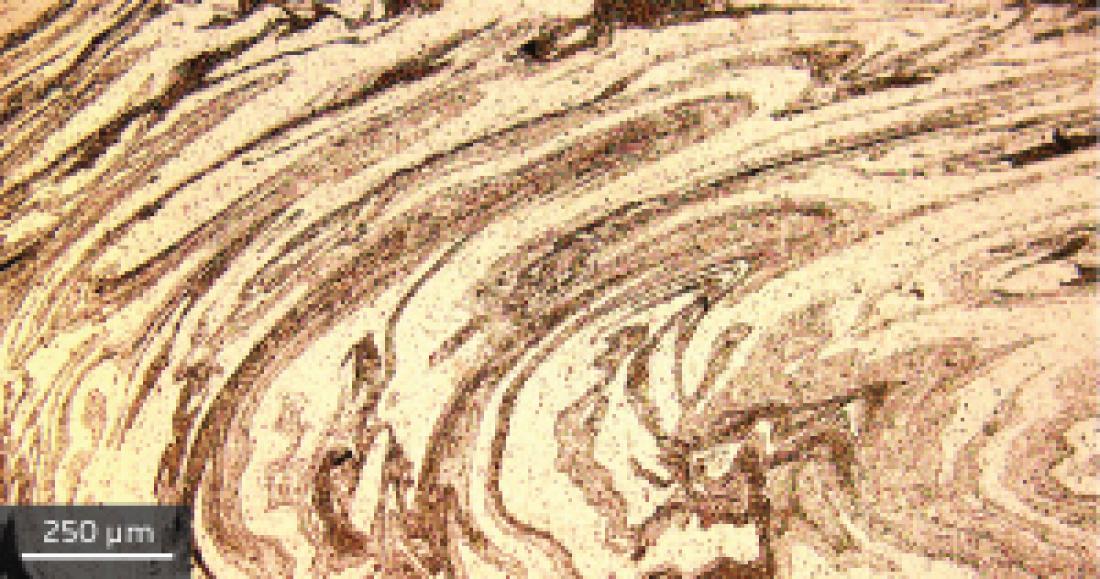

Scanning electron micrograph showing the complex flow patterns, or ‘onion rings’, formed on the advancing side of the welding tool.

© 2014 A*STAR Singapore Institute of Manufacturing Technology

Simple changes in technique can yield big improvements, say A*STAR researchers investigating how welding speed and the placement of materials affect the quality of welds between dissimilar alloys. They discovered that the tensile strength increases with increasing welding speed and becomes even higher when the softer alloy is placed on the advancing side of the weld [1].

Friction stir welding is a relatively new technique for joining flat sheets of metals and alloys together. It is most suited for binding aluminum and aluminum-based alloys — materials that are traditionally difficult or impossible to weld. In addition, it has many advantages over conventional welding methods, including better weld appearance, enhanced mechanical properties, improved safety and lower setup costs.

First demonstrated in 1991, friction stir welding is now widely applied across a diverse range of operations in various industries, including the automotive, aerospace and electronics industries. A recent surge of research interest has focused on how to best apply friction stir welding on dissimilar alloys; in particular, how temperature, stress and material flows affect the quality of welds between AA6061 and AA7075 aluminum alloys — structural materials widely used in the construction of wheel spacers, aircraft fuselages and robotic casings.

Junfeng Guo and his team from A*STAR Singapore Institute of Manufacturing Technology took up the challenge of examining the mechanical properties and microstructures of welds between AA6061 and AA7075 for five different welding settings. They found that a higher welding speed resulted in better welds because less friction heat was generated. The resulting lower temperature meant that the melted materials had little time to recrystallize and consequently their grain size became finer. Similarly, the placement of AA6061 aluminum alloy on the advancing side resulted in better welds because less friction heat was generated.

The researchers examined the ‘onion rings’ — characteristic patterns formed during friction stir welding (see image) — on both the advancing and retreating sides of the weld. They found that multiple vortices formed in the recrystallized zone when the softer A6061 aluminum alloy was placed on the advancing side of the weld. These vortices enhanced material mixing and hence improved the mechanical properties of the weld.

The findings have important implications for materials science and the development of the next-generation friction stir welding machines. “Joining of dissimilar materials is a challenge frequently faced in industries,” says Guo. “Friction stir welding enables the welding of dissimilar materials where fusion welding would have been inappropriate.”

Reference

[1] Guo, J. F., Chen, H. C., Sun., C. N., Bi, G., Sun, Z. & Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Materials & Design 56, 185–192 (2014).