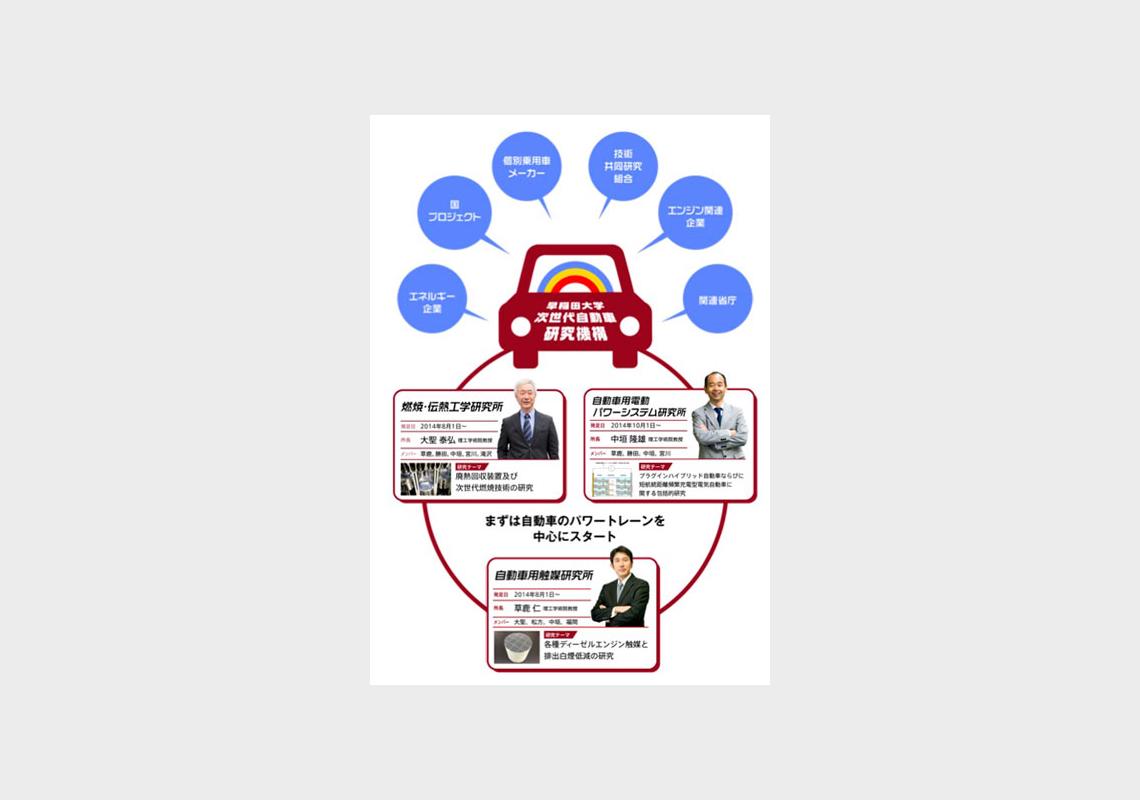

Three project research centers contained within the Research Organization for Next Generation Vehicles. Copyright: Waseda University

April 2014 marked the beginning of the “Research Association of Automotive Internal Combustion Engines” (AICE). Formed by eight Japanese automotive manufacturers, AICE is an unprecedented and full-scale research collaboration consortium operated by organizations throughout Japan. Simultaneously, an industry-academia research collaboration project entitled “Research Project to Develop Technology of Clean Diesel Engine” was established thanks to matching funds from the Ministry of Economy, Trade and Industry (METI) and AICE. In October 2014, the “Strategic Innovation Promotion Program” (SIP) was established under guidance from the Cabinet Office with the goal of establishing competitive superiority for Japanese automotive technology. One of the ten themes for SIP is innovative combustion technology. Organizations throughout Japan are engaged in R&D projects centered on innovative combustion technology in order to gain competitive advantages within the automotive industry.

Universities and public research institutions play an important role as research leaders for this large-scale, nation-wide project. Waseda University was selected as a center for the AICE and SIP projects, and is responsible for the projects’ coordination. Waseda oversees an annual research collaboration budget of 750 million yen for the AICE clean diesel project and 200 to 400 million yen for the SIP innovative combustion technology (Waseda is in charge of the loss reduction team). These budgets greatly surpass those of usual large-scale projects.

In response to national trends and societal needs, Waseda University established the Research Organization for Next Generation Vehicles (nextGV) in October 2014, further solidifying our network of research centers. We discussed the activities and outlook of nextGV with Professor Yasuhiro Daisho (Faculty of Science and Engineering), who serves as director of the organization.

Being entrusted with two large national projects

Readers should understand why automotive industry leaders throughout Japan formed a consortium. The world of automobiles and automotive technology is entering an era of great change. Countries are fiercely competing to solve major global issues such as the reduction of environmental burdens and energy consumption, the improvement of fuel mileage and engine efficiency, and the establishment of new transportation methods and systems to meet the needs of an aging society. In addition to clean energy such as electricity and hydrogen, innovative technology such as automatic driving is being introduced and developed for practical implementation at a dizzying rate. Japan is at the forefront of this competition. One challenge for Japan is the construction of an unrivaled development system for international competition in next-generation technology and systems.

“In order for Japanese manufacturers, universities, and research institutions to establish competitive advantages in next-generation technology, it is not only necessary to compete, but also collaborate,” explains Professor Daisho. “Numerous organizations perform similar research in the fundamental stages of new technology. When one instance of technology is established as a standard, a great number of other research results are shelved without ever seeing the light of day, wasting the labor and costs invested in such research.

The term “precompetitive research collaboration” refers to researchers cooperating at a national level to conduct joint research that reduces inefficiencies and develops next-generation fundamental technology as quickly and efficiently as possible. One example of this type of research is Japan’s national strategy for organizing the Super LSI Technology Research Association in order to establish domestic production for semiconductors. Thanks to first-rate technology, the project succeeded and entered the global market. This prosperous period was known as the era of Hinomaru semiconductors (Hinomaru is the national flag of Japan). Although there was some global criticism directed at the partnership, Western semiconductor industries eventually followed suit with a similar strategy. In contrast to the semiconductor industry, companies within the Japanese automotive industry traditionally develop technology independently. Companies competed with each other, but rarely collaborated. Within other countries however, are technological research associations meant to establish superior development systems through precompetitive research collaboration. This is especially true for automotive industries in European countries such as Germany. Industry experts in Japan eventually began discussing the need for our nation to adopt a similar strategy. Thus a technological research association formed by Japan’s leading automotive manufacturers was established.

Why is it now necessary to focus on internal combustion technology and diesel technology? The fact that automobiles consume more than half of the world’s petroleum is a major issue. It is estimated that the majority of automobiles will continue to be powered by gasoline and diesel engines for another thirty to fifty years. Even with new energy sources such as electricity and hydrogen, hybrid-type engines are still the most realistic and effective option. If it is possible to increase engine combustion efficiency by even 1%, it will have a huge impact on overall petroleum consumption.

“Internal-combustion engines are still of great importance,” notes Professor Daisho. “In order to determine the development objective of our association, AICE has had numerous discussions with officials from automotive manufacturers. Current combustion efficiency for gasoline engines is 39% and for diesel engines 42%. We believe it is possible to raise efficiency to 50% for both kinds of engines. We also intend to decrease CO2 emissions by 30%. These are very lofty targets and there are still many development issues which must be addressed before we are able to meet our goals.”

Diverse projects with mechanical engineering at their core

At the time of its founding, the Research Organization for Next Generation Vehicles contained three distinct research centers (Figure 1). The Research Institute for Combustion and Heat Mass Transfer Engineering, directed by Professor Daisho, houses a research team focused on SIP innovative internal combustion technology and loss reduction. The Research Institute for Automotive Catalysts, directed by Professor Jin Kusaka, leads research in the AICE’s project for purifying exhaust gas from diesel engines. Finally, the Research Institute for Automotive Electric Power System, directed by Professor Takao Nagagaki, conducts R&D for electric micro buses as a new public transportation system.

“Through innovative R&D in mechanical engineering, our goal is to establish internal combustion technology with unprecedented efficiency,” explains Professor Daisho. “Engine R&D requires a great amount of funding. Funding received for the two large-scale projects is being used to acquire space on the Nishi-Waseda Campus and doubling the amount of test equipment. It costs too much time and labor to be involved in advanced research of the development of engines – the heart of automobiles. If detailed computer simulations were possible, it would be possible to significantly reduce development time and costs. An important technological issue for the automotive industry, Professor Jin Kusaka is working to establish a development system which utilizes high level computer simulation. Our ultimate goal is to conduct comprehensive R&D for all next-generation automotive technology by linking research results in internal combustion engines to research in hybrid combustion methods. Our work will include fuel cells and the development of new combustion materials using applied chemistry.”

Boasting 100 years of history in internal combustion engine research

Waseda University boasts a long history in the field of internal combustion technology. The Internal Combustion Research Laboratory was established in the Mechanical Engineering Department in 1918, and will celebrate its 100th anniversary in four years. No can match the quantity or quality of theses published by Waseda University on internal combustion technology. Graduates have formed a vast network that includes the automotive industry.

“Our university’s systems and facilities were given high marks during a site visit by an evaluation team from the national government,” says Professor Daisho. “Past graduates have formed a vast network in the automotive industry which has given birth to activities such as the Waseda University Mobility Research Association and the Waseda University Mobility Symposium (see photograph).”

In addition to research, training of professionals is an important pillar of industry-academia collaboration. Part of our university’s mission is to cultivate an even higher level R&D capability by educating students on advanced research collaboration. These students will enter society as professionals who can support the automotive industry. Waseda actively accepts working professionals from the automotive industry as graduate students. Activities have only just begun, and both research institutions will surely produce great results in the future.

▼This year marks the 34th Waseda University Mobility Symposium, an annual event which was first held in 1981. (The symposium is held by the Waseda University Mobility Research Association and Professor Daisho serves as representative.) Every year, the event attracts about three hundred participants including students, faculty members and past graduates who now work in the automotive industry.