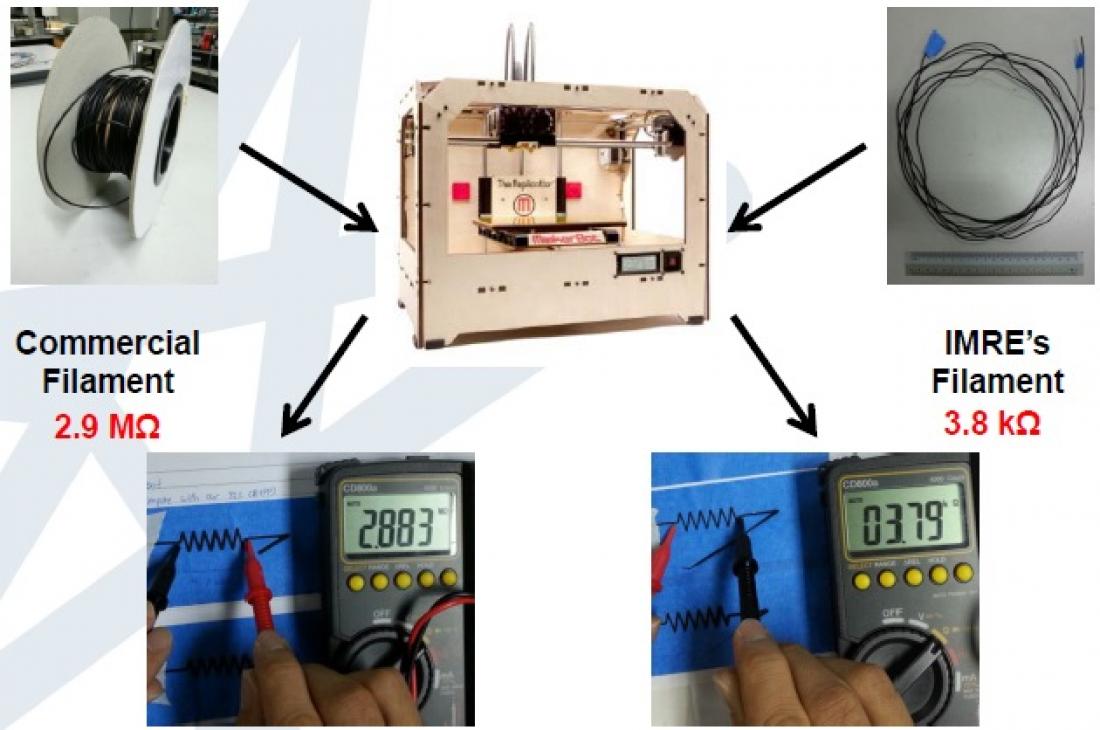

Comparison of electrical resistivity between a commercially-available filament and IMRE’s filament

Singapore—Scientists at A*STAR’s Institute of Materials Research and Engineering (IMRE) have invented a new type of thermoplastic thread that can be used in 3D printers to create functional circuits for use in electrical gadgets.

“I believe this will revolutionise desk-top manufacturing for electronic gadgets,” said Dr Johnson Goh, IMRE scientist and Head of the Science and Engineering Research Council’s (SERC) Nanofabrication and Characterisation Group and Principal Investigator of this project.

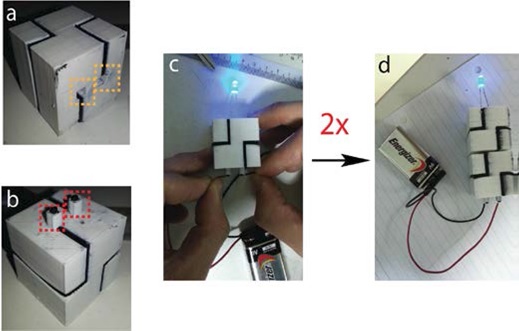

Dr Goh and his team have successfully used this new material to print prototypes such as a USB connector that can light up a LED bulb, complex three-dimensional circuits, and a wearable flexible sensor.

The resistivity of IMRE's thermoplastic material is in the range of 0.5-1.0 Wcm, about 1,000 times more conductive than most commercially available plastic filaments for 3D printing. The filament is strong enough to stay intact throughout the 3D printing process in a conventional thermoplastic 3D printer.

“Objects in various colours, shapes and textures complete with functional circuits including wires, resistors and capacitors, could one day be printed in the comfort of one’s home,” said Dr Kwok Sen Wai, one of the key scientists in the team.

The team has found that using IMRE material to 3D print circuits rather than creating circuits through the conventional etching-and-soldering method is much safer, faster and cheaper. In addition, such circuits have highly uniform conductivity, with less than a 5 percent variation, compared to more than a hundred percent in commercially available conductive filaments.

“We believe that our material will encourage more innovation and entrepreneurship as it will empower people to make prototypes more easily and cheaply,” added Dr Kwok.

IMRE is actively looking for industry partners to commercialise the technology. The new technology is now available for licensing through A*STAR’s commercialisation arm, Exploit Technologies Pte Ltd (ETPL).

Notes to Editor:

In comparison with other newly developed 3D-printable conductive plastic materials outside of Singapore:

“Protoplant”: has a resistivity of about 15 Wcm, and its base material is Polylatic Acid (PLA). IMRE’s material is at least 15 times more conductive, at 0.5-1.0 Wcm.

“MakerGeeks”: has a a resistivity of about 1,000Wcm, and its base material is Acrylonitrile Butadiene Styrene (ABS)-plastic. IMRE’s material is approximately 1,000 times more conductive

Enclosed: ANNEX A – Properties of IMRE’s new conductive thermoplastic

For media queries and clarifications, please contact:

Ada Lim (Mrs)

Assistant Head, Corporate Communications

Agency for Science, Technology and Research

Tel: +65- 6419- 6537

Email: [email protected]

________________________________________________________________

About A*STAR’s Institute of Materials Research and Engineering (IMRE)

The Institute of Materials Research and Engineering (IMRE) is a research institute of the Agency for Science, Technology and Research (A*STAR). The Institute has capabilities in materials analysis & characterisation, design & growth, patterning & fabrication, and synthesis & integration. We house a range of state-of-the-art equipment for materials research including development, processing and characterisation. IMRE conducts a wide range of research, which includes novel materials for organic solar cells, photovoltaics, printed electronics, catalysis, bio-mimetics, microfluidics, quantum dots, heterostructures, sustainable materials, atom technology, etc. We collaborate actively with other research institutes, universities, public bodies, and a wide spectrum of industrial companies, both globally and locally.

For more information about IMRE, please visit www.imre.a-star.edu.sg.

About the Agency for Science, Technology and Research (A*STAR)

The Agency for Science, Technology and Research (A*STAR) is Singapore's lead public sector agency that spearheads economic oriented research to advance scientific discovery and develop innovative technology. Through open innovation, we collaborate with our partners in both the public and private sectors to benefit society.

As a Science and Technology Organisation, A*STAR bridges the gap between academia and industry. Our research creates economic growth and jobs for Singapore, and enhances lives by contributing to societal benefits such as improving outcomes in healthcare, urban living, and sustainability.

We play a key role in nurturing and developing a diversity of talent and leaders in our Agency and Research Institutes, the wider research community and industry. A*STAR oversees 18 biomedical sciences and physical sciences and engineering research entities primarily located in Biopolis and Fusionopolis.

For more information on A*STAR, please visit www.a-star.edu.sg.

ANNEX A

Properties of IMRE’s new conductive thermoplastic

1. This new material from IMRE made by blending carbon powder and polypropylene (commonly-used thermoplastic for many types of packaging and disposable plastic containers) thoroughly, and then producing this mixture as filaments.

2. As this new conductive thermoplastic has a resistivity of only 0.5-1.0 Wcm, and is 3D-printable in a low-cost conventional 3D printer, it is now possible to produce practical circuits based on conductive thermoplastics from low-cost conventional 3D printers.

3. The mechanical strength and heat resistance of this material is significantly higher than existing conductive filaments which are typically layers of conductive core and plastic outer coating. Thus, this new material is able to withstand the stress and high temperatures involved in 3D printing without degrading.

4. It sticks well to thermoplastic materials when used as solder.