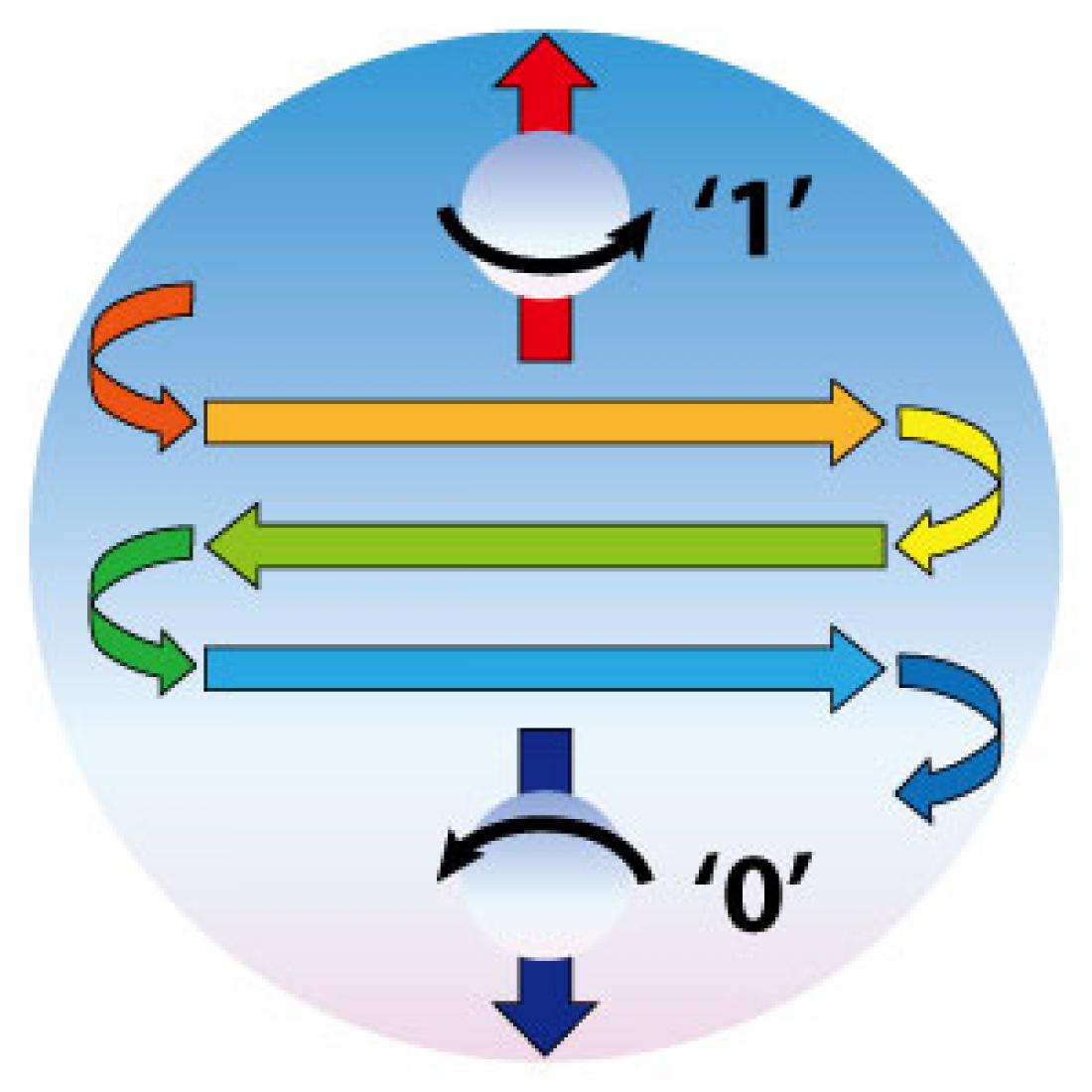

Spin-transfer torque magnetic random-access memories work by using magnetic thin films to control the ‘spin’ on an electron such that it can be used to store digital information.

© 2016 A*STAR Data Storage Institute

The huge energy consumption of the world’s data centers creates an urgent need to develop electronic devices that can process information with reduced power requirements. A device that harnesses the ‘spin’ of electrons offers a route toward this. Researchers at Agency for Science, Technology and Research (A*STAR), Singapore, show how the performance of these so-called spintronic memories can be optimized by careful control of its structure [1].

A spin-transfer torque magnetic random-access memory (STT-MRAM) comprises a stack of thin magnetic layers. One of these layers makes all the electrons in a current flowing through it have the same spin. This spin-polarized current can then change the magnetic properties of a second layer. This relies on the tendency of the electron spins in the material to align along one direction much more than it does another — a property called magnetic anisotropy.

“By having a high anisotropy, the magnet is stable and the memory is able to retain information,” explains Sze Ter Lim from the A*STAR Data Storage Institute. “However, it also means that it is more difficult to switch to the opposite direction because of an effect called damping.” Previous attempts to increase the anisotropy have also led to a proportional increase in damping.

Lim and his co-workers have now developed a STT-MRAM architecture in which the anisotropy can be increased without changing the damping. Their device has a central layer of tantalum. On either side of the central layer is a film of cobalt iron boron (CoFeB), which makes up the required magnetic layers. This in turn is sandwiched between magnesium oxide. The device is grown on a substrate and capped with another layer of tantalum.

Instead of altering the thickness of the magnetic layers, as previous studies have done, the researchers investigated the influence of the outer magnesium oxide. They showed that the anisotropy rises when the top layer thickness is increased from 1.3 nanometers to 2.5 nanometers. But the effect of this change on the damping is minimal.

Lim’s team however does not believe that this change in anisotropy is directly related to the thickness of the magnesium oxide; indeed, similar changes to the thickness of the bottom magnesium oxide film had no effect. Instead, they suggest that the top tantalum atoms intermixed with the magnesium oxide during deposition, and this degrades the interface between the magnesium oxide and the CoFeB.

“The next step is to integrate these optimized materials structures into practical devices and to evaluate its performance,” says Lim.

The A*STAR-affiliated researchers contributing to this research are from the Data Storage Institute