Professor Dong Rip Kim of the Department of Mechanical Engineering has succeeded in fabricating peel-and-stick thin film solar cells (TFSCs) with the collaboration of Stanford team led by Professor Xiaolin Zheng. This method makes possible the overcoming of hardships related to working with traditional solar cells, namely the lack of handling, high manufacturing cost, and limited flexibility while maintaining performance.

Kim is currently in charge of the Hanyang University Nanotechnology for Energy Conversion Lab. His research interests are solar cells, energy conversion devices using nanomaterials, flexible electronics, nanoelectronics, and nanosensors. Among Kim’s recent publications are “Peel-and-Stick: Fabricating Thin Film Solar Cell on Universal Substrates” in the journal of Scientific Reports, “Shrinking and Growing: Grain Boundary Density Reduction for Efficient Polysilicon Thin-Film Solar Cells” in the journal of Nano Letters, and "Thermal Conductivity in Porous Silicon Nanowire Arrays" in the journal of Nanoscale Research Letters.

Most solar cells are now fabricated on Si wafers or glass substrates. The biggest issue for commercialized solar cells is their high price. In addition, due to their fabrication on the Si wafer, the cells are rigid and heavy while being fragile. While they are recognized as one of the most crucial alternative sources of energy, such limitations have prevented wider application of solar cells.

Fortunately, Kim and his colleagues devised an idea to produce a light-weight flexible solar cell on nonconventional or universal substrates that overcomes the limitations of traditional methods while maintaining performance. By doing so, Kim believed that his new cells could broaden the application spectrum of solar cells.

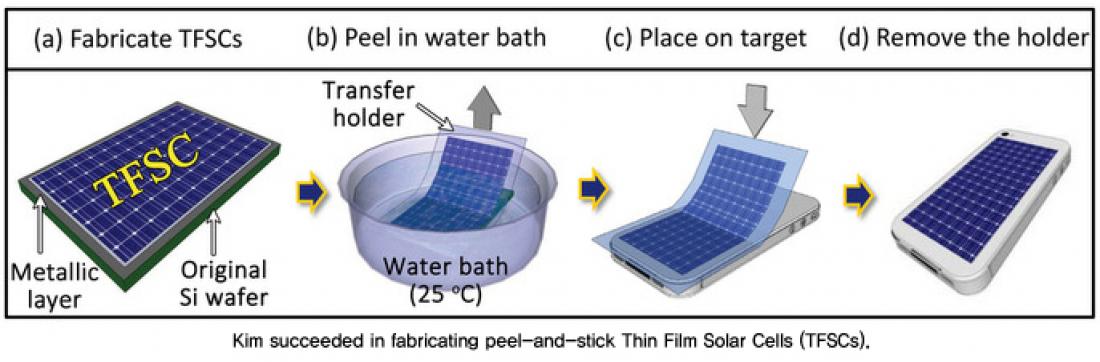

The success comes from using the same traditional fabrication method while adding a metal layer between the fabricated a-Si:H TFSCs and the underlying Si/SiO2 wafer. After numerous attempts and trials, Kim and his colleagues found a method to reliably peel the fabricated TFSCs from the Si/SO2 wafer by using water penetration between the metal layer and the SiO2 layer on the wafer.

The Si wafer is clean and reusable, which is a big cost-saving factor for solar cells. Moreover, as the peeled-off TFSCs from the Si wafer are thin, light-weight, and flexible, it can be attached onto any form or shape of surface like a sticker. Although others have successfully fabricated TFSCs on flexible substrates to realize the flexible solar cells, many efforts have been driven to modify the existing processes for solar cell fabrication, due to the rubber-like properties of the flexible substrates. Importantly, Kim and his colleagues made the light-weight flexible solar cells without modifying any existing fabrication processes, and their performance was maintained even after the transfer. Kim states that their novel technology is not limited to the solar cells only. Numerous other appliances like flexible displays can adopt his method.

“I will continue to focus on creating highly efficient but low costing energy conversion devices with nanotechnology,” Kim said. Moreover, his future research will focus on applying his method in other types of solar cells and in other applications.

Article written by Jisoo Lee: [email protected] for Internet Hanyang News