Dr. Nor Aiman Sukindar using 3D printing technology to fabricate food holders for the food processing industry

Food packaging is held in place on conveyor belts inside custom-made holders to facilitate their filling and sealing. But fabricating holders for every kind of food packaging can be very expensive. Now, IIUM scientists have collaborated with food manufacturing company Organic Gain Sdn Bhd to develop a diverse range of food holders using 3D printing technology. They published their findings in the journal Scientific Review.

3D printing technology has been widely used as an alternative for fabricating three-dimensional products (3D) from computer-aided design (CAD) data files. The process involves printing products one layer at a time and only as needed, reducing waste and saving time. Malaysia’s National Policy on Industry 4.0 highlights 3D printing as a core element for driving local industry.

“Our project is an example of a concerted joint effort with the food industry to utilize 3D printing technology and is in line with UNESCO’s Sustainable Development Goals (SDG),” says project lead Nor Aiman Sukindar of IIUM’s Advanced Manufacturing and Materials Research Unit.

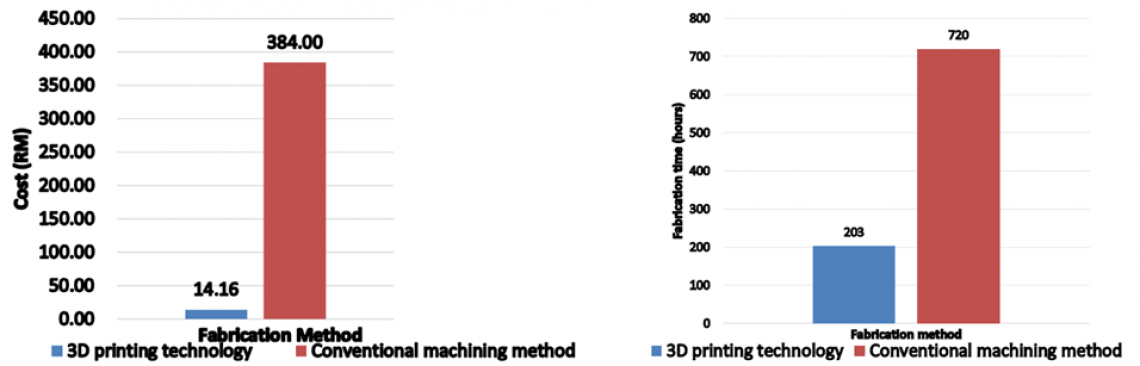

The team used 3D printing to design and print food holders, reducing fabrication costs and time for Organic Gain Sdn Bhd by 96.3% and 72% respectively.

“This was an excellent effort by the team to implement new technologies to provide alternative solutions at a very affordable cost,” says Organic Gain Sdn Bhd chief operating officer Muhammad Adil Bin Dato’ Dr. Ab. Wahab.

(a) Comparison of the total cost to manufacture a set of food holders; (b) Comparison total time to manufacture a set of food holders

Dr. Nor Aiman Sukindar with the Chief Operating Officer of Organic Gain Sdn Bhd, Mr. Muhammad Adil Bin Dato’ Dr. Ab. Wahab

The project was awarded Silver Medal and Outstanding Sustainable Development Goals International Awards in October 2021 at Malaysian Technology Expo 2021 and the Gold Medal in Research and Innovation Technology Competition 2021 organised by Universiti Tun Hussein Onn Malaysia.

It was funded by the Ministry of Higher Education Malaysia under the Public-Private Research Network Grant. Other researchers and students from IIUM that contributed to this project include Sharifah Imihezri Syed Shaharuddin, Shafie Kamaruddin, Ahmad Zahirani Bin Ahmad Azhar, Maizirwan Mel,Insyirah Inani Hasan, Nadhiroh Napri, and Muhammad Afif Md Azhar. The Research Management Centre IIUM, AMTech Research Unit, and Manufacturing and Materials Department, Kulliyyah of Engineering IIUM provided full support to the project.

The team is now actively looking for collaboration and funding for other projects related to 3D printing or additive manufacturing technology to promote sustainable manufacturing technology.

Fabrication, testing and installation of the new food holder in the production line

References:

Implementation of 3D Printing Technology in the Food Industry. Scientific Review, 2021, 74, 50–54.

Contact details:

Ts. Dr. Nor Aiman Sukindar: [email protected]/[email protected]

Advanced Manufacturing and Materials Research Unit (AMTech),

Manufacturing and Materials Department,

Kulliyyah of Engineering,

International Islamic University Malaysia

53100 Gombak Selangor, Malaysia