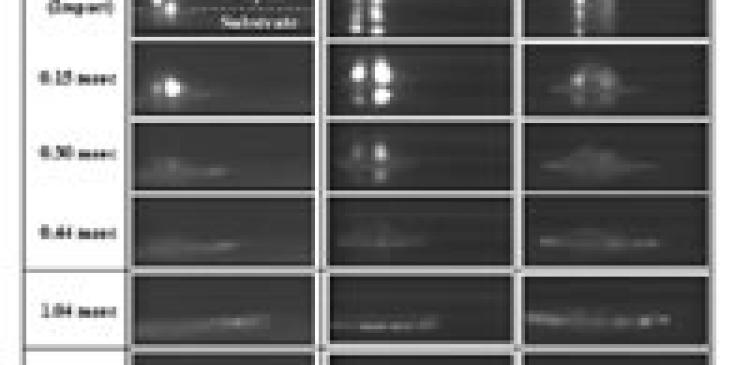

Variation of the spat shapes with substrate temperature and ambient pressure.

However, in spite of the wide spread use of the so-called thermal spraying method for coating large areas of materials, there is still insufficient knowledge about the physical mechanisms—in particular the so-called ‘splat process’ whereby thermally sprayed particles change from a distorted shape at the splash stage, to a disk shape—that govern the properties of sprayed particles with substrates. Such an in-depth understanding is important for improving the control and reliability of thermal spray-based coatings.

Here, Masahiro Fukumoto and co-workers at the Department of Mechanical Engineering, Toyohashi University of Technology, describe their recent findings on the splat formation process to determine why and how disk-shaped splat are formed.

Fukumoto and his group studied the effect of substrate temperature and ambient pressure on the behavior of millimeter sized, molten copper (Cu) droplets free falling onto AISI304 steel substrates.

Important findings included the observation that the porosity at the splat bottom surface dramatically decreased with increasing substrate temperature and decreasing pressure, which implies that substrate wetting by molten droplets during splat flattening may be enhanced by using higher substrate temperatures and lower spray pressures. Notably, good wetting at the splat/substrate interface resulted in disk-shaped splats, and in the opposite case, the formation of splash-splats under poor wetting conditions.

These experiments on the flattening behavior of individual splats will be useful for controlling the properties of coatings on materials by the thermal spraying process.

Reference

• M. Fukumoto, K. Yang, K. Tanaka, T. Usami, T. Yasui, and M. Yamada

‘Effect of Substrate Temperature and Ambient Pressure on Heat Transfer at Interface Between Molten Droplet and Substrate Surface’

Journal of Thermal Spray Technology 20, 48–57, (2011)

Abstract and restricted links: http://www.springerlink.com/content/v81677q1872w52pr/

DOI: 10.1007/s11666-010-9537-5

• Department of Mechanical Engineering, Toyohashi University of Technology, Toyohashi, Aichi 441-8580, Japan