The president of the Daegu Gyeongbuk Institute of Science & Technology (DGIST), President Young Kuk, announced on June 20 (Tue) that a research team led by Dr. Byeong-dae Choi at the Division of Electronics & Information System greatly improved the efficiency of zinc sulfide powder-based electroluminescent devices by applying silver nanofilms. The research team collaborated with Dr. Jong-cheon Park of MS Way (CEO Min-soo Lee) and Professor Seong-ui Lee at the Department of Advanced Materials Engineering, the Tech University of Korea (President Geon-soo Park).

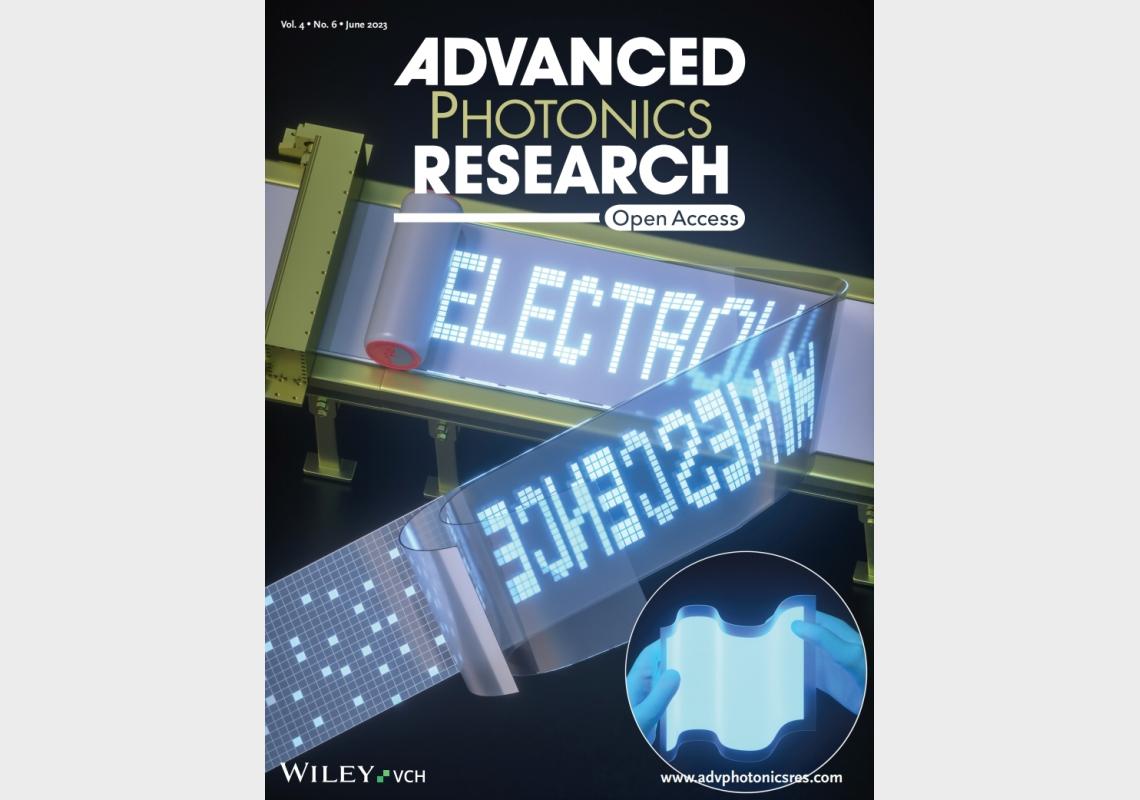

□ An electroluminescent film device is a display/lighting technology that uses the light generated when voltage is applied to a semiconductor material. Since the device is flexible and stretchable, it presents a wide range of applications, with being applicable to not only guide lighting but also foldable and rollable displays.

□ Zinc sulfide powder-based electroluminescent films can be manufactured with just printing techniques. Therefore, their manufacturing process is simpler compared to traditional technologies and does not require expensive vacuum manufacturing equipment. This increases their price competitiveness. However, despite these advantages, they have not been widely accepted due to their low luminous efficiency.

□ The research team at DGIST got their idea from the fact that a device’s efficiency depends on not only electroluminescent efficiency but also the electric current lost in the electrode that transmits the electric current to the emitter. To improve a device’s low efficiency, the research team used silver nanofilms with low electrical resistance as the surface electrode of the emitter.

□ Depending on the lamination method, silver nanofilms can reduce electrical resistance to one-tenth while maintaining the same level of light transmittance as that of traditional transparent electrodes. Dr. Choi’s research team laminated both sides of the light-emitting layer made of zinc sulfide powder with silver electrode nanofilms and minimized resistance-induced energy loss.

□ Minimizing electrode resistance is expected to not only improve the efficiency of light emission but also reduce distortion in image signals when applied to a display. To verify this effect, the research team fabricated microelectrode patterns on a powder-based electroluminescent film with silver nanoelectrodes to create a display pixel array. After applying image signals to the array, the team confirmed that the video plays without any distortion, such as signal dragging.

□ Dr. Byeong-dae Choi stated, “with further research to commercialize this technology, it is expected to be developed into affordable digital signage and film-type lighting.”

□ This study (co-first authors: Dr. Sang-hun Yun and Soo-keun Lee) was funded by the DGIST General Project (D-PIC 4.0) and selected as the front cover article of June 2023’s edition of Advanced Photonics Research, one of the world’s most prestigious photonics journals and published by John Wiley & Sons (Wiley).

Correspondence Author Email Address : [email protected]