The world tallest (634 m) sightseeing and TV broad casting tower – Tokyo Sky Tree uses a massive amount of most advanced TMCP steels.

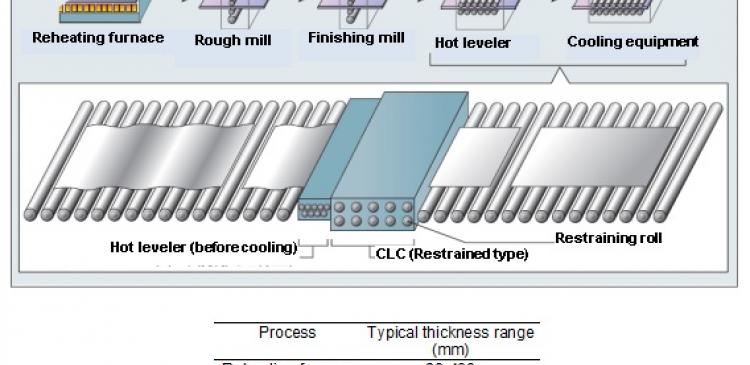

Although steel production dates back about 4000 years, exploration of steel’s potential abilities is still advancing. With an output of about 45%, China dominates when it comes to basic steel production. Japan however is shifting towards so called ‘high-grade steels’. Take for example, the water-cooled thermomechanical control process (TMCP) steels. Relative to traditional water-cooled steel plate processes, TMCP steels offer simultaneous improvements of strength and toughness, while allowing control of the steel’s microstructure.

Nishioka and Ichikawa, researchers from Japan’s largest steel production company, describe recent developments in TMCP Technology in the latest issue of Science and Technology of Advanced Materials Vol. 13 (2012) Issue 2, Page 023001 (http://dx.doi.org/10.1088/1468-6996/13/2/023001).

Manipulation of steel plates and early TMCP technologies originated in Japan. TMCP offers many advantages not least because it produces steel that is easier to work with. Compared to other metals, TMCP steel is much easier to weld, for example. Nishioka and Ichikawa also assess developments of equipment and production technologies for TMCP, and theoretical modeling. The latest applications of TMCP steel are seen in various industries such as shipbuilding, offshore structures, building construction, bridges, pipelines, penstocks and cryogenic tanks. The world tallest (634 m) sightseeing and TV broad casting tower, the Tokyo Sky Tree, was constructed in large part using TMCP steels.

TMCP technology is also likely to provide solutions for resource savings which is critical in a world trying to reduce its carbon emissions.

Related information

[1] Kiyoshi Nishioka and Kazutoshi Ichikawa, “Progress in thermomechanical control process of steel plates and their commercialization”, Science and Technology of Advanced Materials 13 (2012) 023001, doi:10.1088/1468-6996/13/2/023001.

Affiliations:

Kiyoshi Nishioka: Head Office, Nippon Steel Corporation, 2-6-1 Marunouchi, Chiyoda, Tokyo 100-8071, Japan, and Research Center for Advanced Science and Technology, The University of Tokyo, 4-6-1 Komaba, Meguro, Tokyo 153-8904, Japan

Kazutoshi Ichikawa: Plate, Pipe, Tube and Shape Research Laboratory, Steel Research Laboratories, Technical Development Bureau, Nippon Steel Corporation, 20-1 Shintomi, Futtsu, Chiba 293-8511, Japan

---------------------------

Media contacts:

Mikiko Tanifuji

National Institute for Materials Science, Tsukuba, Japan

E-mail: [email protected]

Tel. +81-(0)29-859-2494