Professor Liao (right) and his Postdoctoral fellow Gao Fei (left) develop this energy harvester device in six months’ time.

So far, researchers have developed large devices to use human motion for generating electricity, such as electromagnetic generator-based energy harvesters for capturing energy when people are walking on treadmills or riding bicycles. However, these bulky devices hamper the users’ locomotion and at the same time increase their burden, because of the considerable weight and large interaction force between the harvesters and the human body. This considerably restricts the wide use of these devices. To overcome that, a research team led by Professor Liao proposed and developed a lightweight energy harvester employing piezoelectric macro fiber composites integrated with novel mechanical structures.

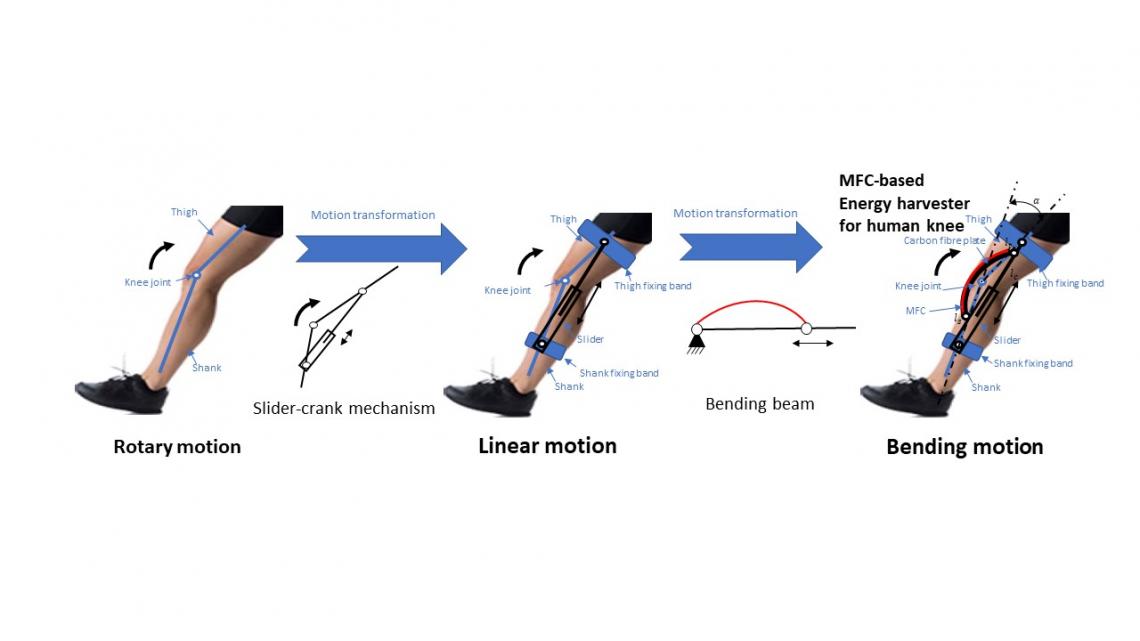

Piezoelectric macro fiber composites are lightweight materials, which can produce electricity under deformation. The proposed energy harvester employs a bending beam and a slider-crank mechanism to capture the motion of the human knee when walking. Then, the captured motion is used to deform piezoelectric macro fiber composites pieces bonded to the bending beam so that electricity is produced when the human knee flexes or extends.

The smart material of the device will bend alongside the motion of the human knee, and convert the biomechanical energy to electricity.

The prototype harvester, made by piezoelectric macro fiber composites, can generate an average power of 1.6 mW, when the wearer walks at about 2-6.5 km/h. The generated electricity is efficient to power common wearable electronic devices such as smart bands. Furthermore, the prototype weighs only 307 grams. When walking with it, the wearer’s metabolic cost is almost the same as that when walking without the device. Unlike the existing electromagnetic generator-based energy harvesters, the lightweight smart materials-based energy harvester can capture energy from human motion without increasing the wearer’s burden. It is expected to significantly promote the use of biomechanical energy harvesters.

Professor Liao stated, “This apparatus will attract much attention from mountaineers and hikers. If they get lost in remote mountains or a wilderness where the power grid is unavailable, the device can derive energy from their motion and convert it to electricity, enabling wearers to continuously monitor their vital signs, know their position, or even send out an SOS signal at any time when they need help. At present, we are focusing on improvement in the performance of the harvester by reducing the weight of the device and increasing energy harvesting efficiency. We plan to commercialise the harvester and market it through cooperating with garment manufacturers to embed the device in sportswear.”

The energy harvester device is extremely light with only 307 grams.

Department of Mechanical and Automation Engineering, CUHK

Established in 1994, the Department of Mechanical and Automation Engineering (MAE) of The Chinese University of Hong Kong (CUHK) celebrates its 25th anniversary this year. The academics of the Department have been striving to research innovative technologies to improve human lives, with a particular focus on robotics and control, design and manufacturing, and energy technology and have gained a worldwide reputation for their significant contributions in these research areas. In teaching and education, in addition to the Mechanical and Automation Engineering Programme (MAEG), another undergraduate programme, the Energy and Environmental Engineering Programme (EEEN), has been launched in recent years. To date, the MAE Department has schooled over 2,000 graduates, many of whom have distinguished themselves in the profession as technical leaders, businessmen, entrepreneurs and even academics and have received prestigious international awards. Their remarkable achievements further affirm the world-leading position of the Department.