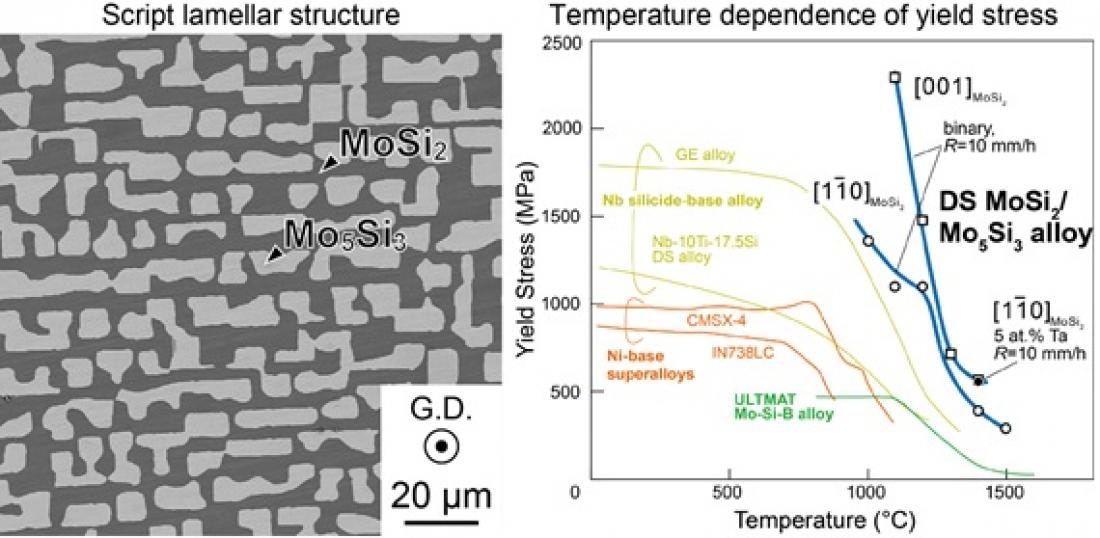

Figure (left): Electron micrographs of directionally solidified (DS) ingots of binary composites. (right): Temperature dependence of yield stress of DS MoSi2/Mo5Si3 eutectic composites and some high-temperature materials. ©2016 Hirotaka Matsunoshita, Yuta Sasai, Kosuke Fujiwara, Kyosuke Kishida and Haruyuki Inui.

Gas turbines are the engines that generate electricity in power plants. The operating temperatures of their combustion systems can exceed 1600 °C. The nickel-based turbine blades used in these systems melt at temperatures 200 °C lower and thus require air-cooling to function. Turbine blades made out of materials with higher melting temperatures would require less fuel consumption and lead to lower CO2 emissions.

Materials scientists at Japan’s Kyoto University investigated the properties of various compositions of molybdenum silicides, with and without additional ternary elements.

Previous research showed that fabricating molybdenum silicide-based composites by pressing and heating their powders – known as powder metallurgy – improved their resistance to fracturing at ambient temperatures but lowered their high-temperature strength, due to the development of silicon dioxide layers within the material.

The Kyoto University team fabricated their molybdenum silicide-based materials using a method known as “directional solidification,” in which molten metal progressively solidifies in a certain direction.

The team found that a homogeneous material could be formed by controlling the solidification rate of the molybdenum silicide-based composite during fabrication and by adjusting the amount of the ternary element added to the composite.

The resulting material starts deforming plastically under uniaxial compression above 1000 °C. Also, the material’s high-temperature strength increases through microstructure refinement. Adding tantalum to the composite is more effective than adding vanadium, niobium or tungsten for improving the strength of the material at temperatures around 1400 °C. The alloys fabricated by the Kyoto University team are much stronger at high temperatures than modern nickel-based superalloys as well as recently developed ultrahigh-temperature structural materials, the researchers report in their study published in the journal Science and Technology of Advanced Materials.

For further information please contact:

Hirotaka Matsunoshita, Yuta Sasai, Kosuke Fujiwara, Kyosuke Kishida and Haruyuki Inui*:

(Department of Materials Science and Engineering, Kyoto University, Sakyo-ku, Kyoto 606-8501, Japan, Hirotaka Matsunoshita, Kyosuke Kishida and Haruyuki Inui are also at the Center for Elements Strategy Initiative for Structural Materials (ESISM), Kyoto University, Sakyo-ku, Kyoto 606-8501, Japan

*E-mail: [email protected])

Article information

“Plastic deformation of directionally-solidified ingots of binary and some ternary MoSi2/Mo5Si3 eutectic composites”,

Hirotaka Matsunoshita, Yuta Sasai, Kosuke Fujiwara, Kyosuke Kishida and Haruyuki Inui:

Science and Technology of Advanced Materials Vol. 17 (2016) p. 1218248

Accepted author version posted online: 28 Jul 2016,

http://tandfonline.com/doi/abs/10.1080/14686996.2016.1218248

Published online: 08 Sep 2016

http://tandfonline.com/doi/full/10.1080/14686996.2016.1218248

Journal Information

Science and Technology of Advanced Materials (STAM) is the leading open access, international journal for outstanding research articles across all aspects of materials science. Our audience is the international materials community across the disciplines of materials science, physics, chemistry, biology as well as engineering.

The journal covers a broad spectrum of materials science research including functional materials, synthesis and processing, theoretical analyses, characterization and properties of materials. Emphasis is placed on the interdisciplinary nature of materials science and issues at the forefront of the field, such as energy and environmental issues, as well as medical and bioengineering applications

http://tandfonline.com/loi/tsta20#.VrgX82fotYU

For more information about the journal Science and Technology of Advanced Materials, contact

Mikiko Tanifuji

Publishing Director

Science and Technology of Advanced Materials

Email: [email protected]