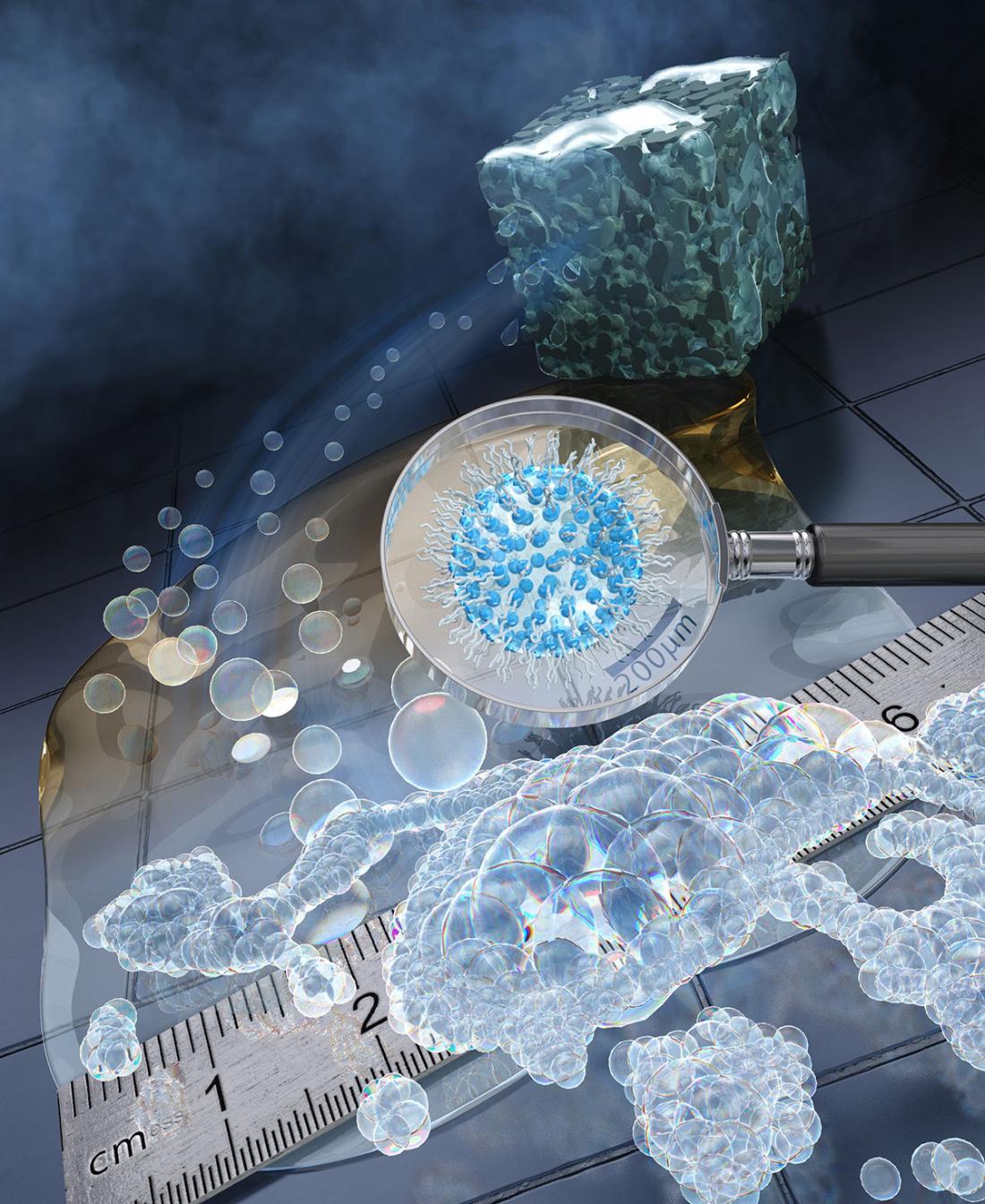

A schematic diagram of how droplets extracted from a sponge self-assemble into a multicellular body structure.

The typical image of a robot is one composed of motors and circuits, encased in metal. Yet the field of molecular robotics, which is being spearheaded in Japan, is beginning to change that.

Much like how complex living organisms are formed, molecular robots derive form and functionality from assembled molecules. Such robots could have important applications, such as being used to treat and diagnose diseases in vivo.

The first challenge in building a molecular robot is the same as the most basic need of any organism: the body, which holds everything together. But manufacturing complex structures, especially at the microscopic level, has proven to be an engineering nightmare, and many limitations on what is possible currently exist.

To address this problem, a research team at Tohoku University has developed a simple method for creating molecular robots from artificial, multicellular-like bodies by using molecules which can organize themselves into the desired shape.

The team, including Associate Professor Shin-ichiro Nomura and postdoctoral researcher Richard Archer from the Department of Robotics at the Graduate School of Engineering, recently reported their breakthrough in the American Chemical Society's publication, Langmuir.

"Our work demonstrated a simple, self-assembly technique which utilizes phospholipids and synthetic surfactants coated onto a hydrophobic silicone sponge," said Archer.

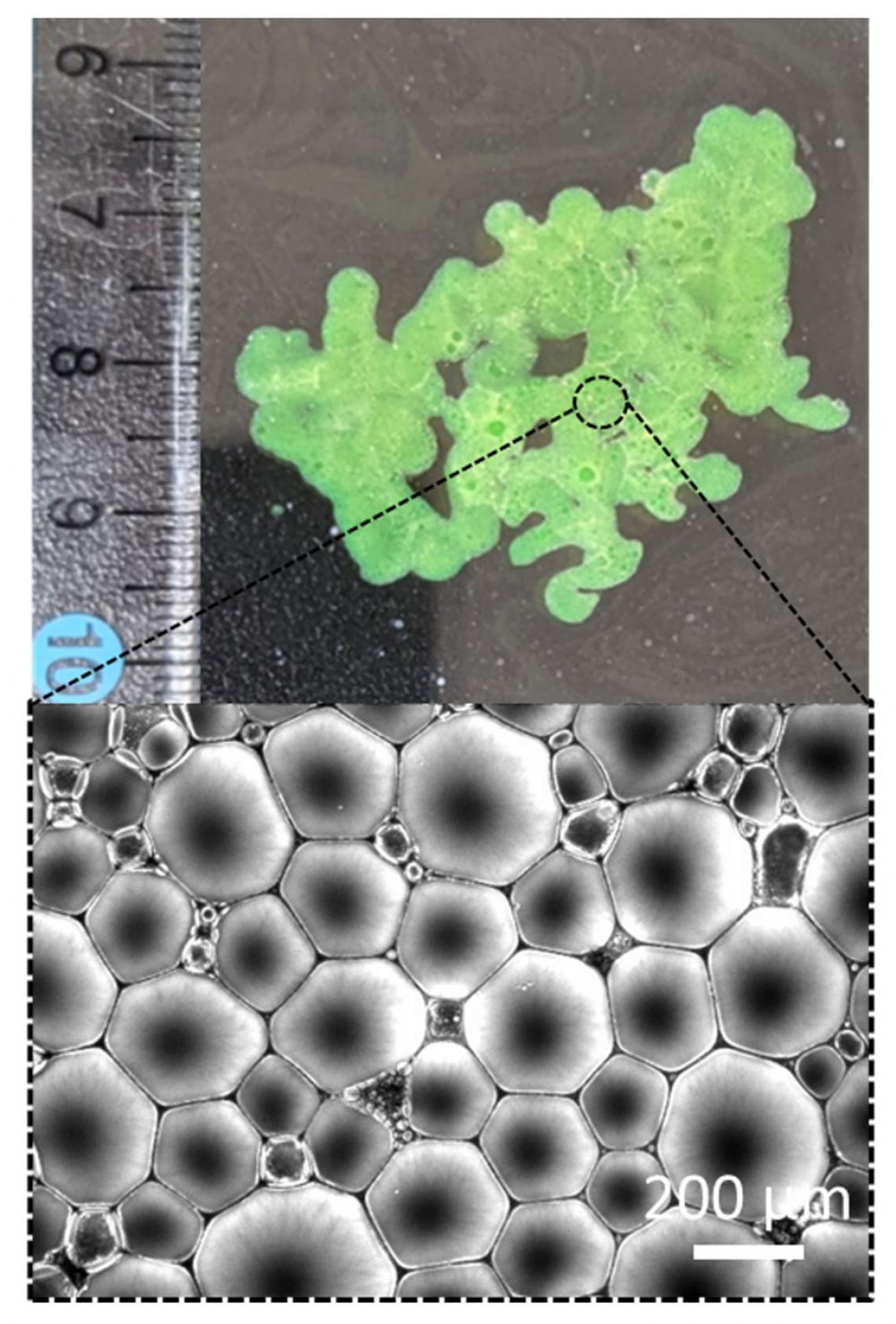

When Nomura and his colleagues introduced water into the lipid coated sponge, the hydrophilic and hydrophobic forces enabled the lipids and surfactants to assemble themselves, thereby allowing water to soak in. The sponge was then placed into oil, spontaneously forming micron sized, stabilized aqueous droplets as the water was expelled from the solid support. When pipetted on the surface of water, these droplets quickly assembled into larger planar macroscopic structures, like bricks coming together to form a wall.

"Our developed technique can easily build centimeter size structures from the assembly of micron sized compartments and is capable of being done with more than one droplet type," adds Archer. "By using different sponges with water containing different solutes, and forming different droplet types, the droplets can combine to form heterogeneous structures. This modular approach to assembly unleashes near endless possibilities."

The team could also turn these bodies into controllable devices with induced motion. To do so, they introduced magnetic nanoparticles into the hydrophobic walls of the multi-compartment structure. Archer says this multi-compartment approach to robot design will allow flexible modular designs with multiple functionalities and could redefine what we imagine robots to be. "Future work here will move us closer to a new generation of robots which are assembled by molecules rather than forged in steel and use functional chemicals rather than silicon chips and motors."

An actually formed multicellular body structure (top) and its enlarged view (bottom).