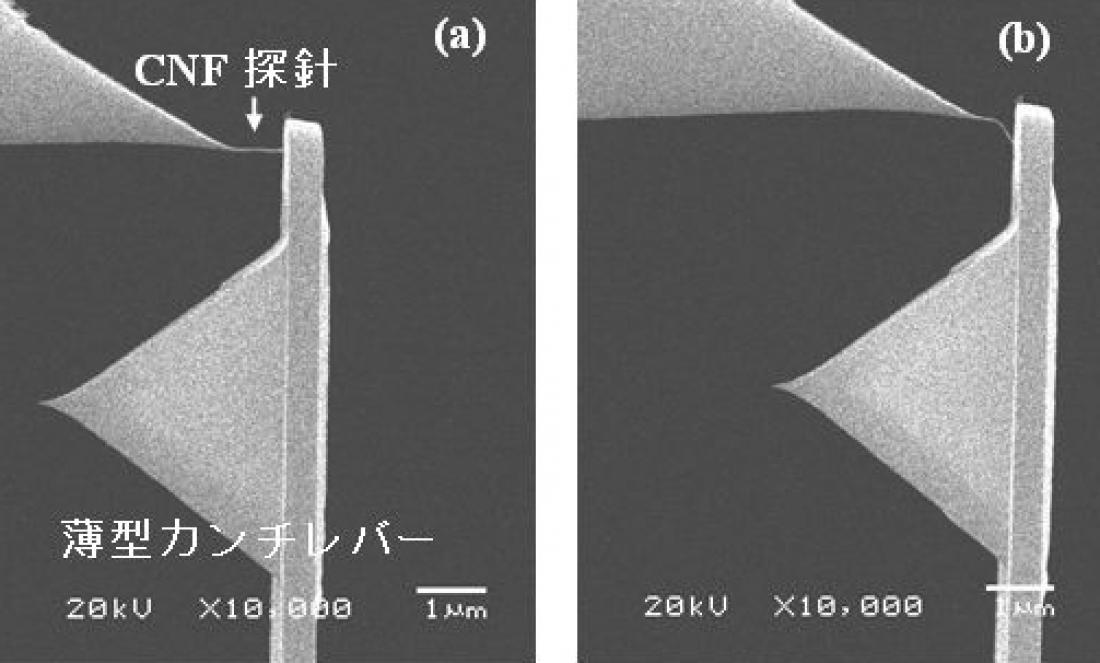

SEM images of CNF probe deformation at the time of (a) contact, and (b) compression (CNF buckling).

Research and development in the "nanometer" area are ceaselessly evolving in the fields of nanotechnology and biotechnology, as typically represented by recent advances in semiconductor technologies. Scanning probe microscopy, which is used to depict irregularities on an atomic level by tracing a solid surface with a sharp needle, is an indispensable analytical tool in the fields of nanotechnology and biotechnology. The external user (Kitazawa) in this project works for the Olympus Corporation, which is a prominent Japanese manufacturer of probes for probe microscopy, developing high-performance probes for various applications. The so-called nanocarbon probe is an ideal type of probe that has one-dimensional nanocarbon such as a carbon nanotube (CNT) at the tip of the probe needle. Carbon nanofibers (CNFs) are a unique type of nanocarbon, and Olympus Corporation is developing processes for the mass production of probes with single CNFs on the tip, with the aim of producing inexpensive, high-performance CNF probes.

In the Nanonet of Nagoya Institute of Technology, unique and originally developed devices, rather than commercially available devices, are supplied for the Nanonet. In this report, we present a collaborative study on the mechanical properties of CNF probes, carried out using a scanning electron microscope (SEM) with a "specially designed sample stage" that allows exact positioning and force control by a piezo drive.

For the full paper, please follow weblinks below.