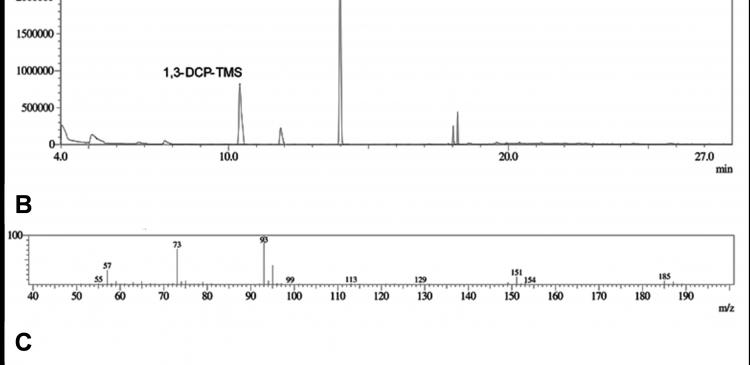

Figure 1 Silylation mechanism of HMDS-TMSOTf. Copyright: Figure 1 and Figure 2 are reprinted from Journal of Chromatography A, 2016, Bai Qin Lee, Che Wan Jasimah Wan Mohamed Radzi, Sook Mei Khor*, A simultaneous derivatization of 3-monochloropropanediol and 1,3-dichloropropane with hexamethyldisilazane–trimethylsilyl trifluoromethanesulfonate at room temperature for efficient analysis of food sample analysis, 1432, 101–110, © 2015 Elsevier, with permission from Elsevier.

Food safety has been a major concern around the world especially in this century where science and technology have been utilized in food preparation and production. Synthetic process was developed to replace traditional food preparation to increase production output and meeting market needs. One of it is soy sauce. In ancient time, soy sauce was produced by mixing soy beans, malts and other materials together and being fermented by bacteria for three months. Today, acid hydrolysis of vegetable proteins is developed to produce artificial soy sauce where acids are added to the raw materials mixture to breakdown the soy proteins. Artificial flavoring is added to mimic the taste of soy sauce. In recent studies, carcinogen 3-monochloropropanediols (3-MCPD) has been found in acid hydrolyzed soy products. In laboratory animal and toxicology testing, 3-MCPD is reported to be carcinogenic and toxic to both kidneys and reproductive organs. Traditional method used for 3-MCPD quantification is chromatography separation. The standard derivatization agent used to derivatize 3-MCPD is Heptafluorobutyrylimidazole (HFBI). However HFBI is very moisture sensitive and expensive. Due to the vigorous reaction towards moisture, HFBI is required to be kept at -20C. Besides, the derivatization process has to be conducted in a heated oven and an inert environment. Due to these difficulties, UM researchers have found an alternative derivatizing agent to derivatize 3-MCPD that is more laboratory friendly. The new derivatizing agent, Hexamethyldisilazane (HMDS) is less sensitive towards moisture at room temperature, thus provides the ease of its storage. HMDS will only derivatize 3-MCPD when a suitable catalyst (Trimethylsilyl trifluoromethanesulfonate, TMSOTf) is added into the reaction system. Further, the activation of HMDS by catalyst is an exothermic process; this removes the need of an oven to initiate the derivatizing process. The Association of Analytical Communities (AOAC) HFBI derivatizing agent cost about USD 61.10 per mL versus HMDS which is only cost about USD 0.62 per mL (price as quoted by Sigma Aldrich). The new derivatizing agent cost 100 times less than the AOAC derivatizing agent. In short, cost efficient room temperature derivatization of 3-MCPD by HMDS coupled with TMSOTf is developed for effective food safety monitoring of soy sauce.

For further information contact:

Dr. Khor Sook Mei

Dr. Che Wan Jasimah

Lee Bai Qin

Department of Chemistry

Faculty of Science

University of Malaya

50603 Kuala Lumpur

Email: [email protected]

Figure 2 (A) Full EI scan of 1,3-DCP-TMS and 3-MCPD-TMS; (B) Characteristic ions of 1,3-DCP-TMS; (C) Characteristic ions of 3-MCPD-TMS. Copyright: Figure 1 and Figure 2 are reprinted from Journal of Chromatography A, 2016, Bai Qin Lee, Che Wan Jasimah Wan Mohamed Radzi, Sook Mei Khor*, A simultaneous derivatization of 3-monochloropropanediol and 1,3-dichloropropane with hexamethyldisilazane–trimethylsilyl trifluoromethanesulfonate at room temperature for efficient analysis of food sample analysis, 1432, 101–110, © 2015 Elsevier, with permission from Elsevier.