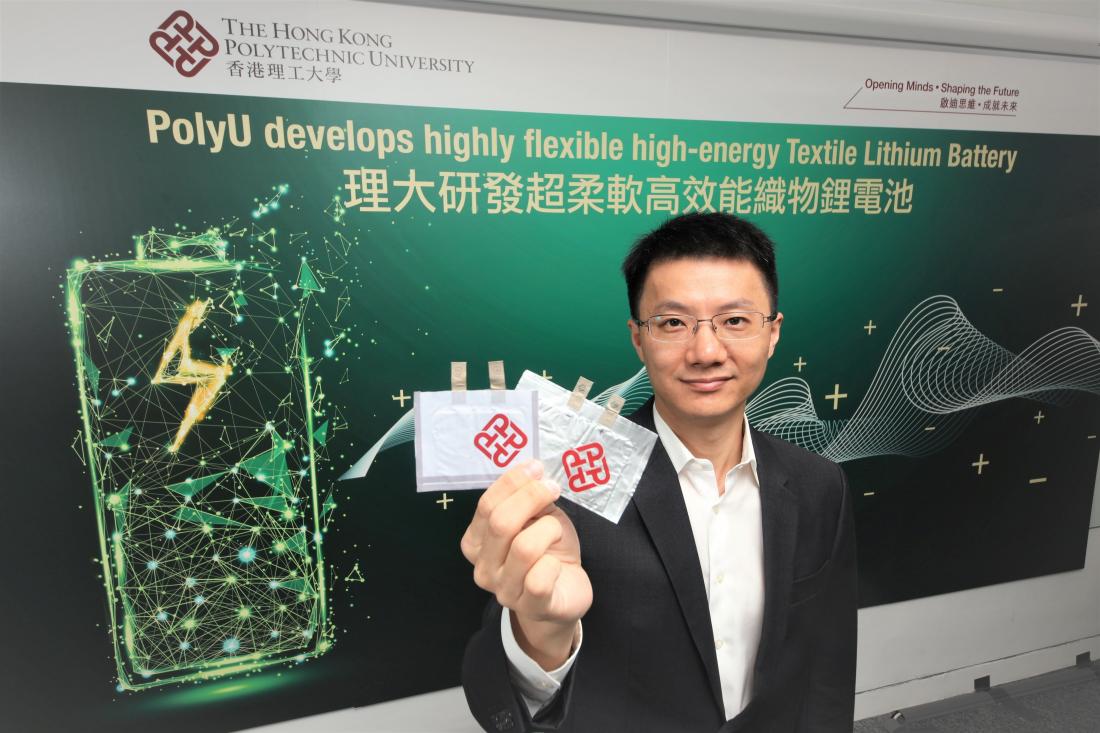

Professor ZHENG Zijian leads the research team of PolyU’s Institute of Textiles and Clothing to develop the highly flexible, high-energy Textile Lithium Battery

(23 May 2019) Researchers at The Hong Kong Polytechnic University (PolyU) have developed a highly flexible, high-energy Textile Lithium Battery that offers more stable, durable and safe energy supply for wearable electronics with a myriad of applications, such as in healthcare monitoring, intelligent textiles, smartphones, Global Positioning System (GPS) tracking and Internet of Things (IoT).

PolyU’s novel lightweight Textile Lithium Battery demonstrates high energy density of more than 450 Wh/L, and excellent flexibility — with a bending radius of less than 1mm, and foldability of over 1,000 cycles with marginal capacity degradation. In comparison, the existing bendable lithium battery can only reach a bending radius of about 25 mm, and with much lower performance of less than 200 Wh/L. The Textile Lithium Battery, of less than 0.5 mm thick, also possesses fast charging/discharging capability, and long cycle life comparable with conventional lithium batteries.

[Please refer to the Annex for detailed comparison of performance between PolyU’s Textile Lithium Battery and other batteries]

The innovation developed by the research team of PolyU’s Institute of Textiles and Clothing (ITC) has snatched three prizes at the 47th International Exhibition of Inventions of Geneva held in April this year, namely a Gold Medal and two Special Merit Awards.

Professor ZHENG Zijian, who leads the ITC research team, said, “Wearable technology has been named as the next global big market opportunity after smartphones. Global market revenues for wearable devices are forecasted to grow by leaps and bounds, of over 20% annually, to reach US$100 billion by 2024 [1]. As all wearable electronics will require wearable energy supply, our novel technology in fabricating Textile Lithium Battery offers promising solution to a wide array of next-generation applications, ranging from healthcare, infotainment, sports, aerospace, fashion, IoT to any sensing or tracking uses that may even exceed our imagination of today.”

Lithium battery is currently the dominant rechargeable battery in the market due to its relatively high energy density and long cycle life. As conventional bulky heavy lithium battery is hard for use in wearable devices, over the past decade, scientists have put in efforts in developing bendable lithium battery, often by using metal foils as current collectors. However, it is only until the emergence of PolyU’s Textile Lithium Battery that the bottlenecks over energy density, flexibility, mechanical robustness and cycling stability being able to be addressed.

Applying PolyU’s patented novel technology of Polymer-Assisted Metal Deposition (PAMD), highly conductive metal, copper (Cu) and nickel (Ni) are uniformly and conformally deposited onto pre-treated fabrics. Such fabricated metallic fabrics, featuring low sheet resistance [2] and large surface area [3], serve as current collectors in battery. After adding active materials to act as cathode and anode, the metallic fabrics, together with separator and electrolyte, are assembled into the Textile Lithium Battery.

Laboratory tests conducted by the ITC team have proven the extremely high mechanical stability, durability and safety of the Textile Lithium Battery under deformation. When the battery is repeatedly folded in half, twisted at different angles or freely crumpled, its voltage window remained unchanged. Bending test showed that the battery can be bent over 1,000 times with marginal capacity degradation. Safety tests conducted by continuous hammering, trimming with scissors and penetrating with nail proved the battery can stably provide power output for the electronic components with no risk of catching fire or burst.

Video on PolyU’s Textile Lithium Battery (link below)

---- End -----

Press Contact: Ms Denise Wong

Communications and Public Affairs Office, PolyU

Telephone : (852) 3400 2131

Email : [email protected]

References

[1] IDTechEx. ‘Wearable Technology 2018-2028: Markets, Players, Forecasts’. Retrieved 8 May 2019 from the link below

[2] Sheet resistance is an important property of conductive materials, quantifying the ability for transporting charges of the materials. The lower the sheet resistance, the faster is the transportation.

[3] In general, the larger the surface areas for loading anode and cathode materials, the greater stability, higher charge/discharge speed and better flexibility is the battery. Applying the PolyU patented PAMD technology to control the deposition time, the thickness and sheet resistance of the metallic yarns can be easily controlled. By weaving the metallic yarns into a 3D metal fabric, its surface areas for loading the active materials, in comparison of a 2D metal foil sheet of the same size, is much enhanced.